DTF transfers are revolutionizing the fabric printing industry, making waves with their innovative technology that blends creativity with efficiency. As businesses and crafters seek high-quality custom transfers, DTF printing technology has emerged as a preferred choice, enabling intricate designs on various materials. This method stands out not just for its vibrancy, but also for overcoming limitations faced by traditional printing methods, including sublimation. With a growing demand for personalized items, DTF transfers offer a practical solution for anyone striving to make their mark in the print-on-demand space. As we delve deeper, we will uncover the remarkable advantages that position DTF transfers as the future of fabric printing.

In today’s dynamic fabric printing landscape, Direct-to-Film (DTF) printing presents a cutting-edge approach to creating stunning custom graphics. This method allows users to easily apply vibrant designs onto various textiles, making it particularly appealing for applications ranging from fashion to promotional products. Compared to conventional techniques like sublimation, DTF offers superior versatility and efficiency, catering to the needs of crafters and small businesses alike. As the demand for personalized print solutions continues to rise, DTF transfers are becoming synonymous with quality and creativity. Embracing this technology not only empowers entrepreneurs but also enhances the overall experience in the ever-evolving world of fabric printing.

The Rise of DTF Transfers in Fabric Printing

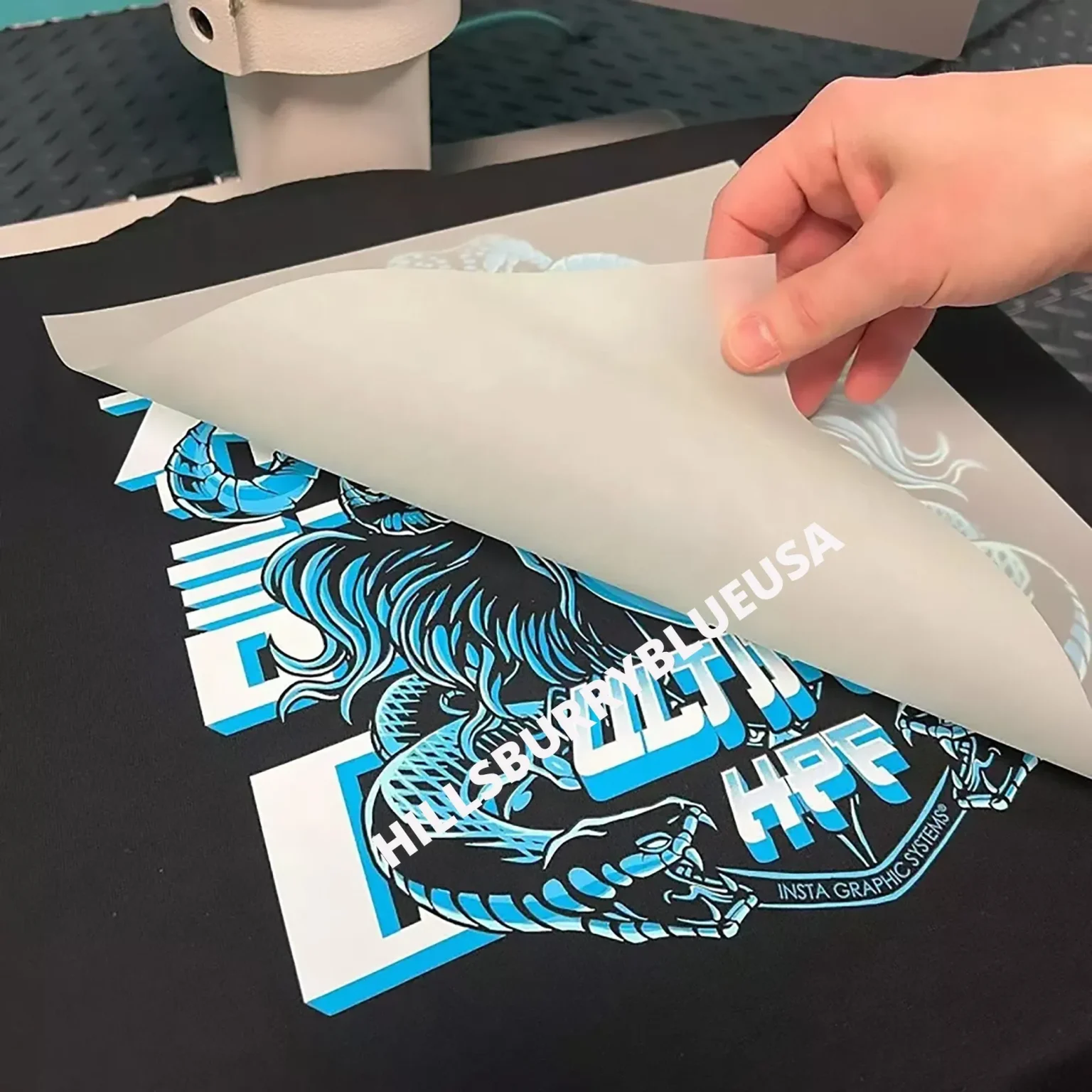

DTF transfers are swiftly becoming a dominant force in the fabric printing industry. Unlike traditional methods, DTF printing technology involves printing designs on a special film, which are then transferred onto fabric using heat. This process not only enhances the vibrancy of colors but also allows for intricate designs that are difficult to achieve with other techniques. As a result, crafters and businesses are increasingly turning to DTF transfers for their versatility and high-quality output.

Moreover, the efficiency of DTF printing is a game-changer for small businesses. It streamlines production processes while maintaining an affordable price point, making it easier for entrepreneurs to enter the custom print market. The ability to produce high-quality designs in-house means that creators can quickly adapt their offerings based on customer demand, ultimately fostering a more dynamic and responsive business environment.

Frequently Asked Questions

What are DTF transfers and how do they relate to fabric printing?

DTF transfers, or Direct-to-Film transfers, are a fabric printing technology that allows for the creation of high-quality, vibrant designs on various textiles. This method is particularly appealing for crafters and small businesses looking to produce custom transfers efficiently.

How do DTF transfers compare to sublimation printing?

While sublimation printing integrates dye into fabric for vibrant colors, DTF transfers offer greater versatility. DTF does not require fabric holes and can yield intricate designs, making it suitable for various applications, especially for those needing precise details without compromising fabric integrity.

What advantages do DTF transfers offer to small businesses?

DTF transfers provide small businesses with the ability to create customized items like t-shirts and tote bags cost-effectively and efficiently. This technology allows them to manage production in-house, giving them creative control over their products while meeting increasing consumer demand.

Are there any user-friendly solutions available for DTF printing?

Yes, recent advancements in DTF printing technology have introduced user-friendly equipment, such as A3 DTF printers, designed for smaller operations. This makes DTF printing accessible for home businesses and startups, lowering barriers to entry in the textile printing market.

What role do web-to-print solutions play in DTF transfers?

Web-to-print solutions like Snuggle DTF streamline the printing process for DTF transfers, allowing businesses to fulfill orders more efficiently. These platforms improve operational efficiency and customer satisfaction by integrating technology with client needs, enhancing the overall DTF printing experience.

How do I choose between DTF transfers and other printing methods for my project?

When choosing between DTF transfers and other methods like sublimation, consider the project’s requirements. If you need high-detail designs without fabric holes, DTF is ideal. For vibrant colors that integrate with fabric, sublimation might be better. Understanding these differences will help you select the right printing method.

| Key Points | Details |

|---|---|

| Attractiveness to Crafters and Small Businesses | DTF transfers provide crafters and small businesses a cost-effective method to create personalized products. The service launched by DesignBundles.net specifically addresses their needs. |

| Investment in Technology | Significant investments in production capabilities have been made, such as EazyDTF adding large-format printers to enhance efficiency and meet demand. |

| Emergence of User-Friendly Equipment | New user-friendly printing equipment, like the A3 DTF printer, is making it easier for home businesses and startups to enter the market. |

| Comparison with Other Printing Methods | Compared to sublimation, DTF transfers offer versatility without fabric damage and meet specific design needs more effectively. |

| Innovative Web-to-Print Solutions | Platforms like Snuggle DTF enhance operational efficiency, making it easier for users to access high-quality prints and streamline the ordering process. |

Summary

DTF transfers are revolutionizing the fabric printing industry with their blend of creativity, efficiency, and accessibility. As technology advances and investments continue, DTF transfers are becoming the preferred printing method, especially for hobbyists and small business owners. The introduction of user-friendly equipment and innovative web-to-print solutions enhances the appeal of DTF, catering to modern consumer demands for customization and quality. With these developments, DTF transfers are not just a trend but an essential element shaping the future of fabric printing.