DTF transfers, or Direct to Film transfers, are revolutionizing the custom printing landscape by offering unmatched versatility for fabric designs. Ideal for creating stunning custom apparel, DTF transfers captivate artisans and businesses alike with their ability to produce vibrant images that maintain incredible detail. Beyond just practical applications, the benefits of DTF transfers allow for a seamless integration into promotional goods and home decor projects, making them a fantastic choice for creative endeavors. By learning how to use DTF transfers effectively, one can explore a myriad of printing applications tailored to individual needs. This guide will illuminate the incredible potential of DTF printing, helping you tap into the booming world of custom apparel and design.

Direct to Film printing, commonly known as DTF printing, is gaining traction as an innovative technique for applying visuals to textiles. This cutting-edge method simplifies the printing process while accommodating a diverse array of materials, ensuring high-quality outcomes and aesthetic appeal for commercial branding and personal projects. From custom garment creation to unique home accessories, the flexibility of DTF transfers creates endless possibilities for showcasing creativity. As we explore various intricacies like DTF transfer benefits and practical applications, it becomes clear that this approach to printing is not just a trend, but a powerful tool for artistic expression.

Understanding DTF Transfers: A Comprehensive Overview

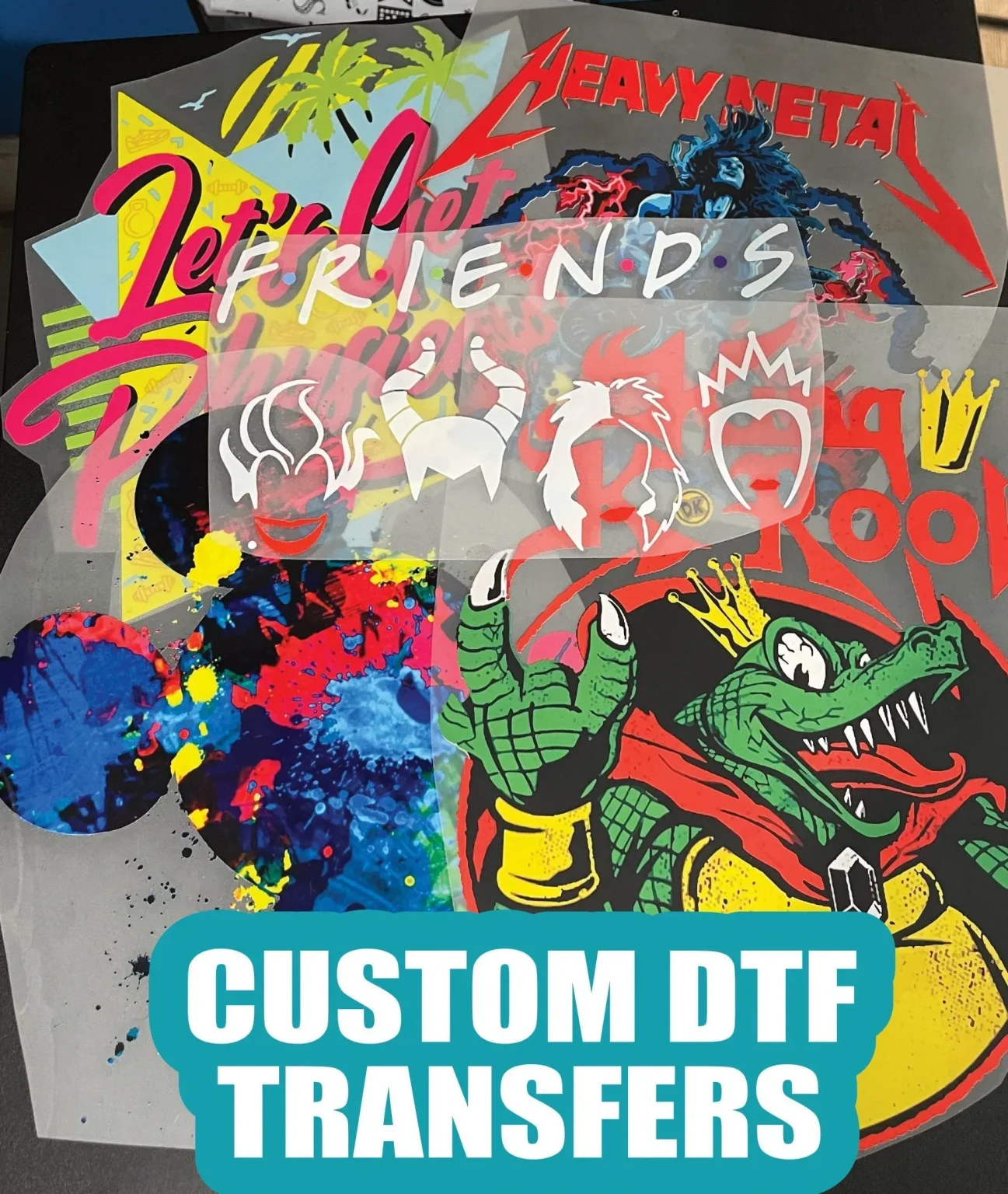

DTF transfers, or Direct to Film transfers, represent a groundbreaking development in the custom printing industry. This process involves printing beautiful, high-resolution images onto a special film, which can then be easily transferred onto various fabrics. One of the key advantages of DTF transfers is their ability to ensure vibrant colors and fine detail, making them suitable for a plethora of applications, ranging from custom clothing to promotional materials. This methodology is not just about functionality; it embodies a pioneering spirit in the world of fabric design.

What sets DTF printing apart from traditional methods, such as screen printing, is its adaptability and ease of use. With DTF, artists and designers can create intricate artworks with a simplicity that saves both time and resources. This process supports a broad range of fabric types, from cotton to polyester blends, showcasing its versatility. As DTF technology continues to evolve, it promises an exciting future for custom apparel printing, allowing creators to explore new avenues of expression with minimal constraints.

How to Use DTF Transfers for Optimal Results

Using DTF transfers effectively begins with understanding the printing process. First, you will need a DTF printer, specialized films, and adhesives designed for heat transfers. After designing your artwork using graphic design software, the next step is printing the image onto the film with a DTF printer. It is essential to ensure that the printer settings are calibrated correctly to achieve the vibrant colors and intricate details that DTF transfers are known for. Once printed, applying the heat press at the correct temperature and pressure ensures a long-lasting bond between the fabric and the transfer.

One of the most fantastic aspects of DTF transfers is their user-friendliness, especially for small businesses and hobbyists looking to expand their creative portfolio. With detailed tutorials readily available online, mastering DTF printing has become accessible to individuals at any skill level. By using the right supplies and following step-by-step guides, you can achieve professional-quality results that rival those of established printing companies. This not only makes DTF transfers a viable option for producing custom apparel but also empowers creators to innovate and personalize their projects.

The Benefits of Choosing DTF Transfers for Custom Projects

DTF transfers offer numerous benefits that are making them a preferred choice among entrepreneurs and artists in the custom printing arena. One of the most compelling advantages is their cost-effectiveness, especially for small or low-quantity orders. Unlike traditional screen printing, which often requires extensive setup and larger order quantities, DTF printing allows for quick production runs without sacrificing quality, enabling businesses to cater to niche markets without incurring heavy expenses.

Additionally, the quality of prints produced using DTF technology is outstanding. With the ability to produce vivid colors and intricate details, custom designs can be replicated with precision, ensuring that the final product retains its intended aesthetic. This high-quality output is crucial for anyone looking to make a statement with their custom apparel or promotional goods. Plus, the wide array of fabric compatibility increases the versatility of DTF transfers, allowing users to experiment with different materials and products seamlessly.

Exploring Creative Applications of DTF Transfers

The range of applications for DTF transfers is vast, extending beyond just custom apparel. Artists and designers utilize DTF technology to create unique promotional items, such as tote bags, hats, and even home decor like cushions and wall art. This flexibility allows for a multitude of creative expressions, making DTF transfers a valuable asset for anyone in the creative industries. With the ability to print on various fabric types and surfaces, the potential for unique, customized products is practically limitless.

Moreover, DTF transfers are increasingly being used for niche markets, where personalized designs are in high demand. For instance, creators can target special events such as weddings, birthdays, or anniversaries by offering custom-designed apparel or gifts that resonate with specific experiences or themes. This level of personalization is appealing to consumers seeking something special and distinct, thereby enhancing market opportunities for businesses that embrace DTF printing.

Innovative Trends Shaping the Future of DTF Printing

As the field of DTF printing evolves, several exciting trends and developments are emerging. One of the most notable trends is the growing focus on sustainability within the printing industry. Many manufacturers are prioritizing eco-friendly materials and production processes. DTF transfers, often requiring less water and energy than conventional printing methods, are being recognized for their potential to reduce environmental impact, appealing to a conscientious consumer base increasingly concerned with sustainability.

Additionally, technological advancements continue to push the boundaries of DTF printing. New printer models and improved ink formulations are paving the way for higher quality and more efficient production processes. These innovations not only enhance the printing capabilities of DTF technology but also make it more accessible to a broader audience, enabling more creators to join the movement. As these trends develop, DTF transfers are expected to play an essential role in redefining custom printing standards and practices.

Embracing the DTF Revolution in Custom Apparel Printing

The DTF printing revolution is transforming the custom apparel landscape, and for good reason. As traditional methods face limitations, DTF transfers provide a modern solution that meets the demands of both professional designers and casual creators alike. With the rapid pace of change in fashion and consumer preferences, adapting through DTF technology allows businesses to stay relevant and competitive by rapidly producing fresh and appealing designs.

Moreover, the ease of use associated with DTF transfers means that anyone interested in custom apparel can engage with the process, regardless of their experience level. With online resources, guides, and community support, aspiring printers can learn and innovate quickly. This democratization of fabric printing not only enhances creativity but also fosters a sense of community among DIY enthusiasts and professional print shops, encouraging collaboration and shared learning in the process.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, involve printing high-quality images onto a special film which can then be heat-transferred onto fabric. This process not only produces vibrant colors but also maintains intricate details, making it ideal for custom apparel and promotional items.

How to use DTF transfers in custom apparel printing?

Using DTF transfers in custom apparel printing is easy. First, print your design onto the DTF film. After printing, apply a layer of adhesive powder and cure it. Then, position the film on your fabric and apply heat using a heat press. This simple process makes DTF ideal for small businesses and hobbyists.

What are the benefits of using DTF transfers for apparel?

The benefits of DTF transfers for apparel are numerous. They provide versatility with fabric types, ease of use compared to traditional methods, high-resolution quality for standout designs, and cost-effectiveness for low to medium print runs, making them a preferred choice for custom apparel.

What fabrics can DTF printing be applied to?

DTF printing can be applied to a wide variety of fabrics including cotton, polyester, and various blends. This versatility allows DTF transfers to cater to different printing needs across custom apparel and home decor.

What are some creative applications of DTF transfers?

DTF transfers are perfect for creating custom apparel such as t-shirts and hoodies, promotional goods like branded merchandise, and unique home decor items such as personalized cushions and blankets, showcasing their creative potential.

How does DTF printing compare to other printing methods?

DTF printing stands out due to its ease of use, ability to produce high-quality prints, versatility with fabric types, and cost-effectiveness for short runs. Compared to methods like screen printing, DTF requires less setup and is ideal for custom creations.

| Key Points | Details | |

|---|---|---|

| What Are DTF Transfers? | DTF (Direct to Film) transfers involve printing high-quality images onto a special film that can be transferred onto fabric using heat. | |

| Advantages of DTF Transfers | 1. Versatile Material Compatibility 2. Ease of Use 3. High-Resolution Quality 4. Cost-Effective for Short Runs | |

| Creative Applications | 1. Custom Apparel (T-shirts, hoodies) 2. Promotional Goods (Bags, merchandise) 3. Home Decor (Cushions, blankets) | |

| Latest Trends | 1. Technological Advancements 2. Sustainability Awareness 3. Creative Collaboration | |

Summary

DTF Transfers represent an innovative and flexible solution for custom printing needs, allowing for creative expression across various mediums. As businesses and individuals alike seek efficient methods for producing high-quality designs on fabric, DTF transfers emerge as a top choice. This process offers significant advantages such as ease of use, compatibility with diverse materials, and cost-efficiency, particularly for smaller print runs. Additionally, the DTF method supports a variety of applications, from custom apparel to unique home decor items. As we embrace sustainability and technological advancements, the future of DTF transfers looks promising, empowering artists and brands to truly unleash their creativity.