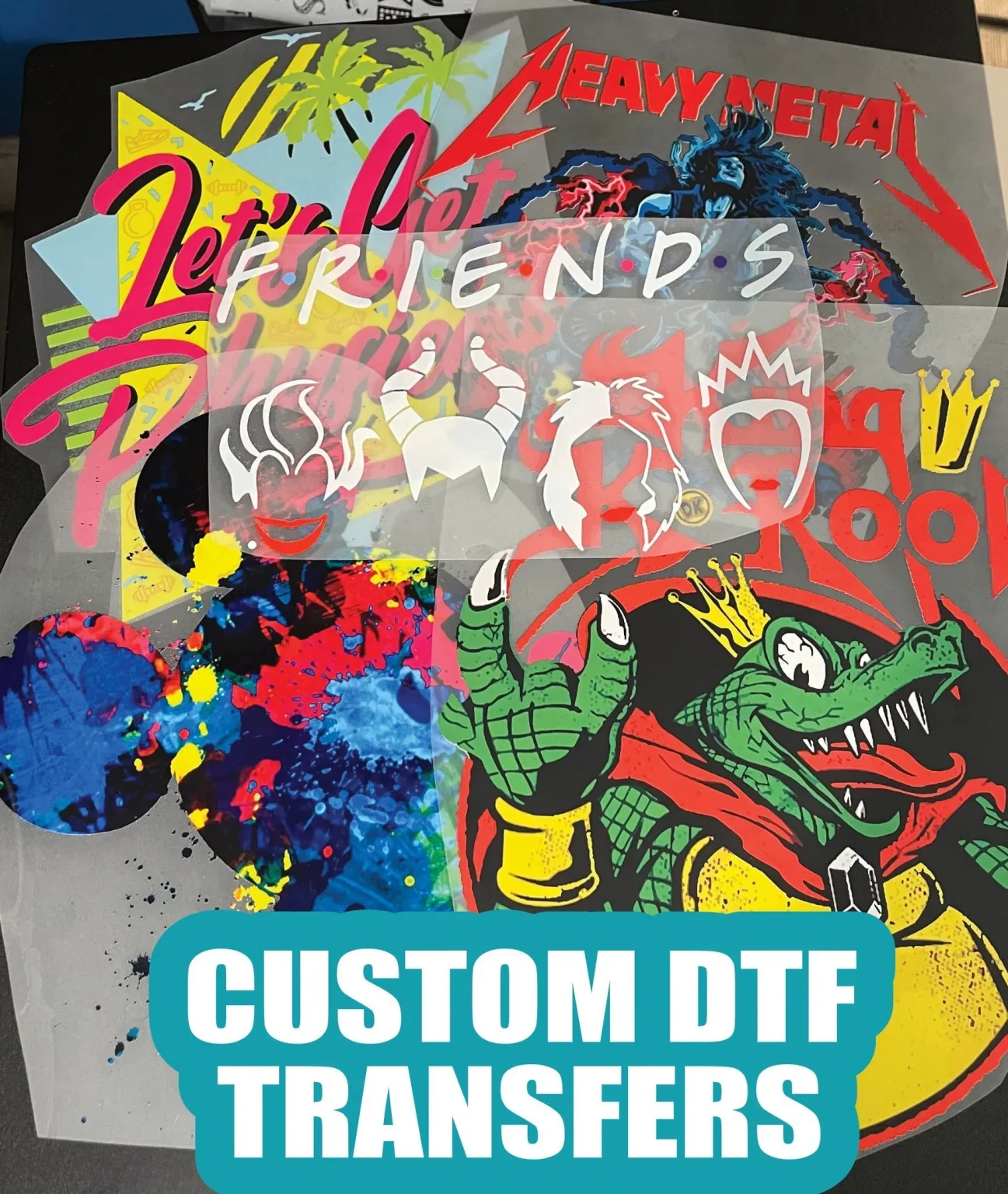

DTF transfers, or Direct to Film transfers, are at the forefront of the custom apparel revolution, transforming the way designs are printed and applied to fabrics. This advanced DTF technology empowers designers to create stunning, high-quality images that can be seamlessly transferred onto a variety of materials, enhancing both creativity and efficiency in apparel production. As the custom apparel market evolves, the versatility and durability offered by DTF printing solutions are making them increasingly popular among fashion entrepreneurs and businesses alike. With a strong focus on sustainable printing practices, DTF transfers are paving the way for eco-friendly options that appeal to environmentally conscious consumers. In this article, we will delve into the exceptional benefits and latest advancements in DTF transfers, highlighting their role in shaping the future of custom apparel.

Direct to Film printing solutions, commonly referred to as DTF transfers, represent a revolutionary shift in how customized clothes are produced. This innovative process involves meticulously printing drawings onto special film sheets, which are then heat-pressed onto diverse fabrics. As the wave of change sweeps across the textile industry, many designers and brands are realizing the potential of this cutting-edge method for producing intricate designs in a cost-effective manner. Notably, DTF technology not only supports a wide range of textiles but is also gaining traction due to its contribution to sustainable printing practices that aim to reduce environmental impact. In the following sections, we will explore the myriad advantages of embracing DTF technology in the realm of custom apparel.

What Makes DTF Transfers Stand Out?

DTF transfers stand out in the custom apparel landscape for several compelling reasons. First and foremost, the quality of prints produced using DTF technology is unmatched by traditional methods. The printed designs are not only vibrant but also showcase fine detail, which is essential for complex artwork, logos, and unique graphics. These vibrant colors and intricate patterns result from the innovative ink formulation and printing techniques, making DTF the preferred choice for designers who seek to push creative boundaries.

Moreover, DTF transfers demonstrate exceptional durability, proving to be resistant to fading, cracking, and peeling even after multiple washes. This durability is crucial for apparel businesses that strive for customer satisfaction, as consumers expect their clothing to maintain its appearance over time. By choosing DTF technology, businesses can ensure longevity in their products, fostering brand loyalty and repeat customers.

DTF Printing: An Economical Choice for Startups

The economic advantages of DTF printing cannot be overstated, particularly for startups venturing into the custom apparel market. With the decreasing costs of DTF printers and supplies, new entrepreneurs can establish their businesses without the burden of large upfront investments. This cost-effectiveness enables them to experiment with various designs and fabric choices while managing budget constraints.

Additionally, the efficiency of DTF transfers contributes to a faster return on investment. The streamlined production process allows for quick turnaround times, making it possible for startups to meet customer demands promptly. As a result, businesses can scale up their operations and attract more clients, positioning themselves favorably in the competitive landscape of custom apparel.

Sustainable Practices in DTF Transfer Technologies

Sustainable printing practices have gained significant traction in the fashion industry, and DTF technology is at the forefront of this movement. Unlike traditional printing methods that may rely on environmentally harmful substances, DTF transfers prioritize eco-friendliness by utilizing water-based inks and recyclable films. This approach significantly reduces waste and decreases the carbon footprint associated with apparel production.

Manufacturers are continuously researching and developing new processes aimed at making DTF transfers even more sustainable. By investing in eco-friendly materials and inks, companies can produce high-quality prints while also meeting the growing demand for environmentally responsible products. This aspect not only resonates with conscientious consumers but also positions brands as leaders in sustainable fashion.

Customization Capabilities with DTF Technology

One of the standout benefits of DTF technology is its ability to deliver unparalleled customization options for apparel designers. The printing process enables the creation of intricate, full-color designs on various fabric types, including cotton, polyester, and blends, making it an excellent choice for diverse product lines. This versatility allows businesses to cater to a wide audience, offering unique designs that resonate with different market segments.

Moreover, the high degree of customization available through DTF transfers sets the foundation for unique marketing strategies. Businesses can create personalized products, such as custom apparel for special events, team jerseys, or promotional merchandise, which helps in establishing a strong brand identity. This flexibility in design options empowers companies to differentiate themselves in the saturated custom apparel market.

Industry Perspectives on the Future of DTF Transfers

Industry experts are optimistic about the future of DTF transfers, acknowledging their potential to outperform traditional screen printing and heat transfer methods. DTF technology offers better adaptability and superior finishes, allowing print shops to expand their offerings and stay competitive. Many are embracing DTF printing not just as an addition to their services but as a core technology that could redefine the future of apparel printing.

As consumer preferences evolve and demand for personalized, high-quality items increases, businesses that adapt to DTF printing are likely to gain a competitive edge. By integrating DTF technology into their operations, apparel producers can meet the growing expectations of quality and customization, ensuring their place in a rapidly changing industry landscape.

The Versatility of DTF Transfers Across Fabrics

The versatility of DTF transfers is one of its most appealing attributes. Capable of adhering to a wide array of fabrics, including different blends and materials, DTF technology empowers businesses to produce custom designs on everything from t-shirts and hoodies to athletic wear and accessories. This capability not only expands the product range but also attracts a diverse customer base, meeting various market needs.

Furthermore, the adaptability of DTF printing means that designers can experiment with different fabrics while maintaining print quality. This flexibility allows for innovative creations that cater to seasonal trends and special releases, thus keeping apparel lines fresh and engaging. By incorporating various textiles into their offerings, businesses can differentiate their products and stand out in the crowded retail space.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct to Film transfers, are a modern printing technology that allows for designs to be printed onto a specialized film and then heat-pressed onto various fabrics, making them ideal for custom apparel. This method produces vibrant and highly detailed images that can comply with different material types, including cotton and polyester, ensuring versatility in apparel production.

Why is DTF printing gaining popularity among custom apparel businesses?

DTF printing is increasingly popular due to its cost-effectiveness and ease of use. The decreasing prices of DTF printers make it accessible for small business owners and independent designers, enabling them to produce high-quality custom apparel without significant upfront investments.

How does DTF printing compare to traditional printing methods in terms of durability?

DTF printing offers outstanding durability compared to traditional methods like screen printing. DTF transfers are less prone to fading and cracking, even after many washes, which enhances customer satisfaction and ensures longevity in custom apparel.

What sustainable practices are associated with DTF transfers in the apparel industry?

The DTF printing process is considered more environmentally friendly than traditional printing methods, especially as manufacturers increasingly use eco-friendly inks and recyclable materials. These practices are crucial as the fashion industry shifts toward sustainability, making DTF transfers a more attractive option for conscious brands.

Can DTF technology be applied to a variety of fabrics in custom apparel production?

Yes, one of the key advantages of DTF technology is its versatility; it can be used on various textiles, including cotton, polyester, and blended fabrics. This flexibility allows designers to create custom apparel for diverse market needs.

What are the main benefits of using DTF transfers for custom apparel?

DTF transfers offer several benefits, including quick production times, high-quality prints, cost-efficiency, and ease of application. This user-friendly technology allows businesses to produce intricate designs and cater to client demands swiftly, making it a valuable asset in the custom apparel industry.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers are a cutting-edge printing solution transforming custom apparel. |

| What are DTF Transfers? | Designs are printed on a film which is then applied to fabric using heat and pressure, allowing for intricate and vibrant designs. |

| Recent Developments | Includes rising popularity, better quality, and ongoing sustainability discussions making DTF more viable for businesses. |

| Benefits of DTF Transfers | Fast production, cost-effectiveness, ease of application, high customization options. |

Summary

DTF Transfers are revolutionizing the custom apparel industry through their advanced technology and versatility. This innovative printing method stands out due to its high-resolution capabilities, enabling designers to produce vibrant and intricate designs on various fabrics. With significant benefits including fast production times, durability, and user-friendly application, DTF is proving to be a cost-effective solution for both small businesses and established brands. Moreover, as sustainability becomes increasingly important in fashion, DTF technology is evolving to incorporate eco-friendly practices. Embracing DTF Transfers means staying ahead in the competitive market by meeting consumer demands for quality and sustainability.