DTF transfers, or Direct-to-Film transfers, are transforming the landscape of creative printing with their remarkable ability to deliver vibrant, long-lasting designs on various fabrics. This cutting-edge technology not only enhances the quality of printed images but also simplifies the overall printing process, making it an ideal choice for both enthusiasts and professionals alike. By utilizing specialized DTF printing techniques, users can achieve stunning visual results that stand up to wear and washing. To maximize the benefits of DTF transfers, having the right tools and knowledge is essential, including understanding the DTF transfer process and applying effective DTF printing tips. As the market continues to evolve, these innovative printing methods are becoming increasingly accessible, paving the way for a new era of custom apparel creativity.

In the realm of fabric decoration, digital printing has unlocked a myriad of possibilities, with Direct-to-Film (DTF) methods leading the charge for versatility and quality. Also referred to as DTF printing, this technique effectively combines advanced ink technology with precise heat application to produce durable images on textiles. By utilizing specialized DTF transfer tools and adhering to essential printing practices, users can explore a new dimension of design possibilities. Whether for personal projects or commercial ventures, understanding the nuances of the DTF transfer process is crucial for unleashing creativity in the apparel industry. With the growing popularity of these innovative techniques, now is the perfect time to dive into DTF printing and elevate your custom design game.

Key Techniques for Effective DTF Transfers

Mastering the key techniques involved in DTF transfers is essential for achieving high-quality results. The foundation begins with design creation; using high-resolution PNG formats with transparent backgrounds is crucial. This not only maintains the integrity of your designs but also amplifies the vibrancy and detail of the final print. By focusing on these aspects, you ensure that every transfer reflects the intended artistry, standing out on various fabric types.

Another critical technique is the selection of the right DTF transfer film. These specially coated films are engineered to optimize ink absorption, ensuring proper adhesion when heat is applied. Understanding the properties of different films can significantly impact the durability and brightness of the prints. This technique combines a keen eye for design with knowledge of material science, making it a vital component in the DTF printing process.

Understanding the DTF Printing Process

The DTF printing process involves several strategic steps to ensure quality outputs. The first step is printing with specialized DTF printers, which may include modified inkjet models. These printers are crucial as they support the unique inks and films necessary for creating vibrant transfers. Epson printers are particularly popular within this community due to their ability to handle the specific demands of DTF printing.

Following the printing phase, the choice of inks adds another layer of sophistication to the process. Unlike traditional inks, water-based inks used in DTF transfers are engineered for better adhesion and longevity on fabrics. This differentiation ensures that prints can endure the rigors of wear and washing without fading or peeling. Understanding each aspect of this process is imperative for those looking to excel in DTF printing.

Essential Tools for Successful DTF Printing

Equipping yourself with the right tools is paramount for successful DTF transfers. First and foremost, a DTF printer—whether dedicated or modified—is non-negotiable for producing high-quality prints. It’s not just about the technology but also about having the right specifications that align with the DTF transfer process.

In addition to a printer, a quality heat press machine is crucial for ensuring that your transfers adhere properly to the fabric. This machinery regulates not just temperature but also pressure—two vital elements for achieving optimal results. Furthermore, having access to high-quality adhesive powder and professional design software will streamline your workflow and elevate the overall quality of your prints. Each tool plays a significant role in the integrity of the final product.

DTF Printing Tips for Quality Results

For those engaged in DTF printing, conducting preliminary tests on various fabrics is a beneficial practice. Testing allows you to fine-tune settings like temperature and pressure, ensuring that you consistently achieve high-quality results. Such tests are invaluable in identifying any potential issues before scaling up to larger batches, saving time and resources in the long run.

In addition to testing, regular maintenance of both your printer and heat press cannot be emphasized enough. A well-maintained machine will produce consistent results and avoid common pitfalls such as ink clogging or temperature inconsistencies. As you grow more proficient, experimenting with layering techniques can also enhance your designs, but be cautious to adjust press settings accordingly to maintain the integrity of the fabric and transfers.

Recent Trends in DTF Transfer Technology

The landscape of DTF printing is evolving, particularly as smaller businesses and entrepreneurs increasingly adopt this technique. Many are drawn to DTF due to the falling prices of equipment and supplies, which lower the barrier to entry for creative endeavors. This shift has encouraged innovation, leading manufacturers to develop user-friendly DTF printing kits tailored for home use.

The rise in DIY DTF kits represents a significant trend as more individuals explore the world of custom apparel printing. As accessibility improves, the market is poised for growth, allowing artistic creators to transform their ideas into tangible products. This democratization of technology not only fosters creativity but also opens up new opportunities for those looking to turn their passion into a business.

The Future of DTF Printing in Custom Apparel

Looking ahead, the future of DTF printing appears bright, especially within the custom apparel sector. As technology progresses, advancements will likely enhance the speed and efficiency of DTF transfer methods, making it easier for users to create stunning designs. Additionally, it’s expected that more businesses will incorporate DTF printing into their workflows, recognizing its potential to produce high-quality, durable prints that resonate with consumers.

The continual improvement in DTF transfer methodologies, combined with growing interest from individual entrepreneurs and small businesses, suggests that this printing technique will remain a cornerstone in the fabric decoration industry. With ongoing developments, participants in this field are encouraged to stay informed, exploring new resources and techniques to refine their skills and adapt to changing market dynamics.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

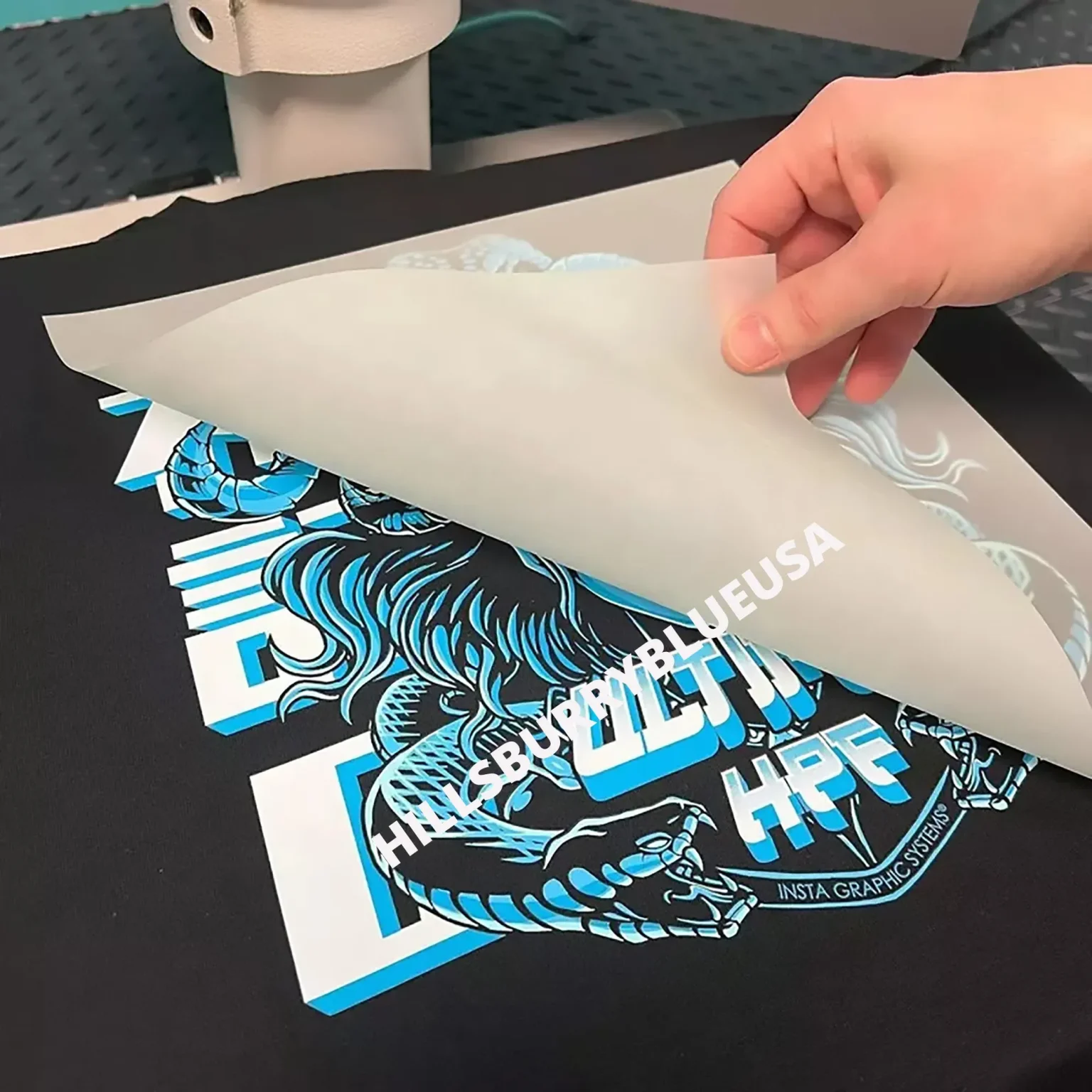

The DTF transfer process, or Direct-to-Film printing, involves printing designs onto a special film using water-based inks. The printed film is then coated with adhesive powder and heat-pressed onto fabric. This method allows for vibrant, durable designs that can withstand washing and wear.

What are the essential DTF printing tools required for successful transfers?

To achieve successful DTF transfers, you’ll need a dedicated DTF printer (or a modified inkjet printer), a heat press machine, adhesive powder, and design software like Adobe Illustrator or CorelDRAW to prepare your images.

What are some key DTF printing tips to enhance print quality?

To enhance DTF printing quality, always test prints on various fabrics to find optimal settings. Regularly maintain your printer and heat press to prevent clogs, and explore layering techniques for intricate designs, adjusting heat and time accordingly.

What types of inks are used in DTF transfers?

DTF transfers utilize specially formulated water-based inks designed for optimal adhesion and durability. These inks are different from traditional printing inks and are crucial for ensuring that designs remain vibrant through washing and usage.

How does the heat pressing technique impact DTF transfers?

Heat pressing is critical in the DTF transfer process as it activates the adhesive powder, bonding the design to the fabric. Optimal heat settings between 325-340°F and appropriate pressure are necessary to achieve a secure transfer.

Why has DTF printing gained popularity among small businesses and hobbyists?

DTF printing has gained popularity due to the decreasing costs of equipment and supplies. The availability of DIY DTF printing kits has made this method accessible for small businesses and home-based entrepreneurs, fueling the growth of the DTF market.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | Direct-to-Film (DTF) transfers are becoming popular in printing and apparel for vibrant, durable prints. |

| Techniques | 1. Preparation: Design creation in high-resolution PNG, film printing with coated transfer films. 2. Printing Process: Use specialized DTF or modified inkjet printers with water-based inks. 3. Heat Transfer: Heat press at optimal temperatures (325-340°F) to bond transfers. |

| Essential Tools | 1. DTF or modified inkjet printer. 2. Heat press machine. 3. Adhesive powder. 4. Design software (e.g., Adobe Illustrator). |

| Tips for Success | 1. Conduct test prints on various fabrics. 2. Maintain printers and heat presses regularly. 3. Explore layering techniques for advanced designs. 4. Educate customers on post-production care. |

| Recent Developments | Increased adoption by small businesses and home entrepreneurs due to decreasing costs, leading to a rise in DIY DTF printing kits. |

Summary

DTF transfers are transforming the landscape of custom printing by offering a user-friendly and beneficial solution for fabric decoration. By utilizing DTF printing, creators can achieve stunning designs that are not only visually appealing but also durable and long-lasting. This method is highly accessible, making it ideal for both personal projects and commercial endeavors. As technology improves, the capabilities of DTF transfers expand, offering new opportunities for artistic expression in the fashion and promotional items sectors. With a growing array of resources and tools available, now is an excellent time to embrace DTF transfers and leverage their potential to elevate your printing projects.