DTF transfers, or Direct to Film transfers, are at the forefront of modern clothing design, offering a powerful tool for creative entrepreneurs and established brands alike. This innovative printing method combines advanced technology with sustainability, allowing for vibrant, full-color designs to be transferred onto various fabrics without wasteful traditional practices. In the realm of custom garment design, DTF printing not only enhances creativity but also supports eco-friendly apparel production practices. As designers and small businesses seek efficient solutions, understanding the DTF transfer process becomes crucial for staying ahead in a competitive industry. This article explores the myriad benefits and techniques associated with DTF transfers, ensuring you’re equipped to make the most of this remarkable technology.

The landscape of apparel production is evolving, and one of the standout methods gaining traction is Direct to Film printing, commonly referred to as DTF technology. This technique facilitates the transfer of intricate designs onto garments, providing an alternative to traditional printing methods that often involve excessive waste. By leveraging the benefits of sustainable printing practices, designers are now able to create custom pieces that not only look stunning but also contribute to eco-conscious efforts in the fashion industry. The DTF transfer mechanism, characterized by its efficiency and high-quality output, positions it as an essential tool for those looking to make a mark in custom garment design. In this article, we will delve deeper into how DTF transfers work and their pivotal role in shaping the future of sustainable fashion.

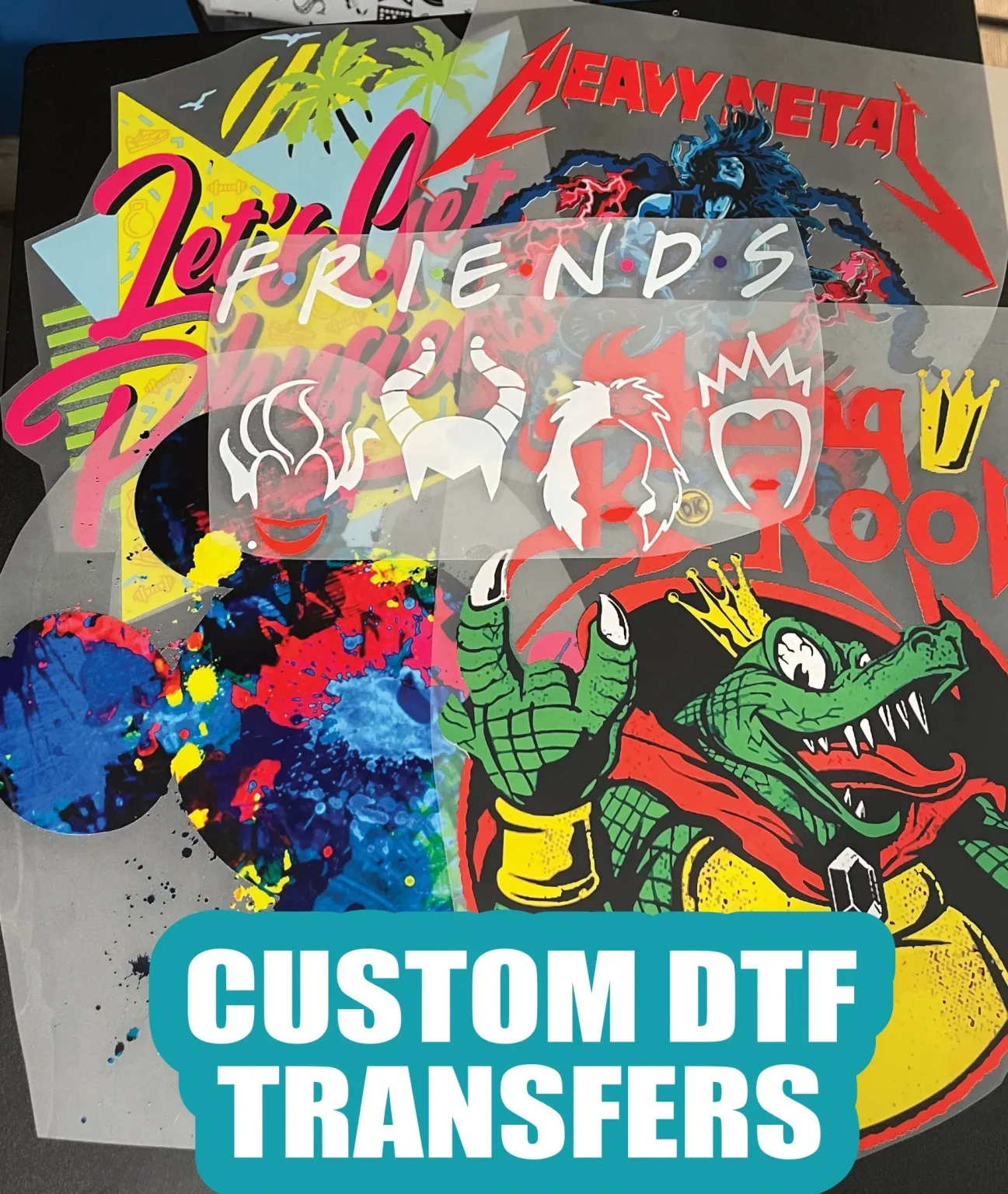

Understanding the DTF Transfer Process

The Direct to Film (DTF) transfer process is a revolutionary method in the textile printing industry that allows for high-quality, detailed designs to be applied to garments. Initially, designs are printed onto a specialized film using advanced inkjet technology. This method not only produces vibrant colors but also offers an extensive palette, making it ideal for custom garment design. The entire procedure requires minimal setup time compared to traditional methods, streamlining the process for designers and businesses.

Following the printing stage, a heat-activated adhesive powder is sprinkled over the design which bonds with the ink. When heat is applied using a professional heat press, the design is effectively transferred to the fabric. This two-step process of DTF printing ensures durability and longevity of the prints, allowing them to withstand normal wear and tear, further establishing DTF technology as a reliable option for sustainable apparel production.

Frequently Asked Questions

What is the process of DTF printing and how does it work?

DTF printing, or Direct to Film printing, involves a two-step process where vibrant designs are printed onto a special film. After printing, a powder adhesive is applied, bonding the ink securely. The design is then transferred to the garment using heat, allowing for high-quality, detailed imagery that stands out.

How do DTF transfers contribute to sustainable apparel production?

DTF transfers are a sustainable option in apparel production as they eliminate the need for water and reduce ink waste compared to traditional methods. This eco-friendly approach minimizes environmental impact, making DTF a preferred choice for environmentally conscious designers.

What are the advantages of using DTF transfers for custom garment design?

The advantages of using DTF transfers for custom garment design include high-resolution print quality, vibrant colors, and ease of use. DTF technology allows for intricate designs that remain durable after washing, making it perfect for custom apparel production.

Can DTF transfers be used on various fabric types?

Yes, DTF transfers are versatile and can be applied to a wide range of fabric types, including cotton, polyester, and blends. This adaptability makes DTF printing a popular choice for diverse custom garment design projects.

What equipment do I need to get started with DTF transfers?

To start with DTF transfers, you’ll need a DTF printer, special DTF film, adhesive powder, and a heat press. It’s important to ensure that your printer settings are compatible with the film to achieve optimal results in your custom designs.

What trends are currently influencing DTF printing in the fashion industry?

Current trends in DTF printing include a focus on customization, sustainability, and technological advancements. More designers are utilizing DTF for unique creations, and eco-friendly practices are becoming integral as the fashion industry moves towards responsible production.

| Key Points | Description |

|---|---|

| What Are DTF Transfers? | A printing method that transfers vibrant designs onto fabrics using a two-step process without water, reducing waste and promoting sustainability. |

| How DTF Printing Works | DTF involves printing designs onto a special film, applying an adhesive powder, and then using heat to transfer the design to the garment, allowing for intricate details and vibrant colors. |

| Benefits of DTF Transfers | 1. **Sustainable Printing**: Less waste and water usage compared to traditional methods. 2. **Quality of Print**: High-resolution, vibrant prints that withstand washes. 3. **Ease of Use**: Accessible process for hobbyists and small businesses, making custom garment production easier. |

| Crafting with DTF: A Step-by-Step Guide | 1. Design your artwork using software. 2. Print on DTF film in mirror mode. 3. Apply adhesive powder to warm print. 4. Transfer with heat press. 5. Finalise garment ready for use. |

| Current Trends in DTF Printing | An increasing number of designers are adopting DTF technology for its customization possibilities and eco-friendly nature, evidenced by newer services aimed at enhancing user experience in custom transfer printing. |

| The Future of DTF in the Crafting Community | As DTF technology continues to evolve, it is expected to play a larger role in fashion, fostering environmentally friendly practices and increased opportunities for creativity through customization. |

Summary

DTF Transfers are transforming the landscape of modern apparel production by offering innovative, sustainable solutions for designers and small business owners. As the crafting community increasingly adopts this method, it becomes clear that DTF technology not only enhances the quality and efficiency of garment production but also promotes eco-friendly practices that resonate with today’s environmentally conscious consumers. With its accessibility, vibrant print quality, and potential for customization, DTF Transfers are set to lead the way in the future of fashion.