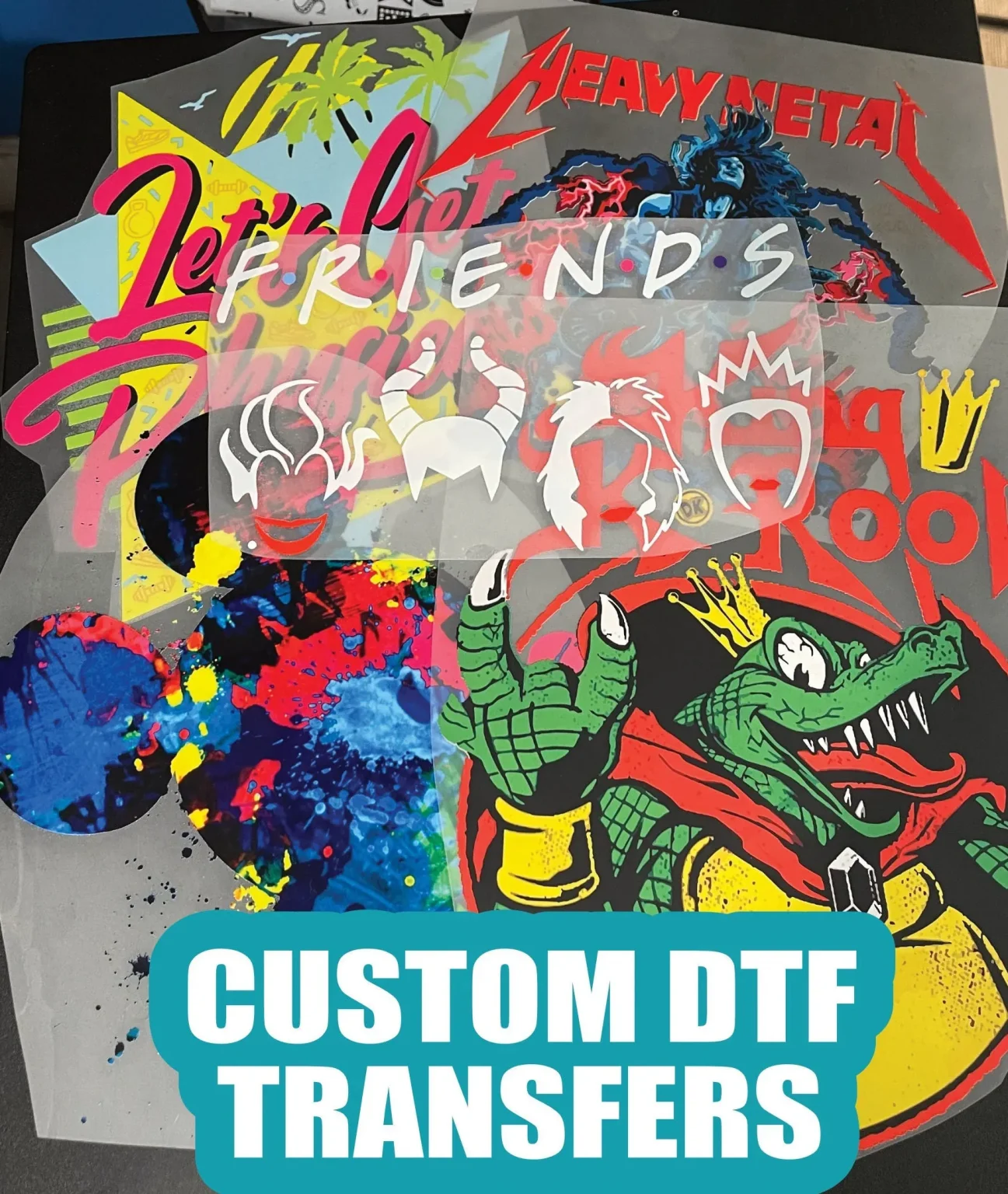

In the vibrant world of textile design, **DTF Transfers**—short for Direct-to-Film transfers—are rapidly emerging as a preferred choice for innovators and creators alike. This cutting-edge printing technology redefines how apparel customization is approached, allowing for intricate details and vivid colors that truly stand out. With an increasing focus on sustainable printing practices, DTF transfers not only minimize waste but also cater to a wide range of fabric types, from cotton to polyester. As businesses strive to meet consumer demand for eco-friendly options, DTF printing is leading the charge by combining efficiency with creative freedom. In this article, we will delve into the mechanics of DTF transfers, their myriad benefits, and why they are hailed as a transformative force in the industry.

Also known as Direct-to-Film printing, DTF Transfers have revolutionized the landscape of textile creation, making it easier than ever for designers to bring their visions to life. This innovative transfer method allows for seamless application on diverse fabrics, enhancing the possibilities for unique apparel designs. Amid the rising trend of eco-conscious production, the DTF technique stands out for its sustainable approach, yielding minimal waste and lower environmental impact. As brands and crafters alike embrace this advanced technology, we will investigate how its versatility and quality set it apart from traditional printing methods like screen printing and sublimation printing. Immerse yourself in the exploration of DTF printing and discover how it aligns creativity with sustainable values in the apparel industry.

Understanding DTF Printing Technology

DTF printing technology, or Direct-to-Film transfers, represents a significant shift in how fabrics are selected and printed upon. Unlike traditional methods, DTF utilizes a film that allows for intricate designs to be printed and then heat-transferred onto a variety of fabrics. This process not only improves the accuracy of color detail but also enhances the vibrancy of the prints. The high-quality inks used in this method ensure that the designs stand out, making it ideal for creating eye-catching apparel that appeals to a broad audience.

Moreover, DTF technology is incredibly versatile, making it suitable for different fabric types, including cotton, polyester, and even blends. This adaptability means that designers are not limited to specific materials, allowing them to explore various styles and textures in their textile designs. As the industry shifts towards more innovative and sustainable printing practices, DTF printing stands at the forefront of this transformation.

The Advantages of DTF Transfers in Apparel Customization

One of the standout benefits of DTF transfers is their exceptional versatility, particularly in the realm of apparel customization. Whether you’re creating bold graphics for T-shirts or intricate designs for hoodies, DTF technology seamlessly handles dark and light fabrics alike. This capability is particularly advantageous for businesses seeking to expand their product offerings without being constrained by fabric limitations often imposed by methods such as dye sublimation.

Additionally, DTF transfers ensure high-quality prints that are durable and long-lasting. As colors maintain their vibrancy and designs resist peeling or cracking over time, apparel created via this method can withstand the rigors of everyday wear. This durability is essential for brands focused on quality and customer satisfaction, leading to repeat business and loyalty.

Sustainability in DTF Printing Practices

Sustainability is increasingly becoming a focal point within the textile design industry, and DTF printing answers this call by minimizing waste. Unlike traditional screen printing methods that often produce surplus stock, DTF transfers allow for on-demand production. This results in greater efficiency and less unused inventory, thereby reducing the overall environmental footprint associated with apparel manufacturing.

Additionally, DTF technology utilizes less water and fewer harmful chemicals compared to conventional printing processes. This eco-friendly approach not only aligns with the growing consumer demand for sustainable products but also helps businesses position themselves as leaders in environmentally conscious practices. By adopting DTF transfers, companies can contribute positively to the planet while delivering high-quality, market-ready apparel.

Exploring Recent Innovations in DTF Technology

The rapid evolution of DTF technology has led to remarkable innovations that enhance its capabilities. Recent advancements include the introduction of large-format printers capable of producing larger designs, catering to an expanding market that requires both speed and quality. Companies at the forefront of this technology, such as EazyDTF, have invested heavily to ensure they meet rising consumer demands for customized apparel and promotional products.

Moreover, the user-friendly platforms emerging in the DTF landscape have simplified the transfer printing process, allowing designers and small businesses to produce tailored products without minimum order requirements. This accessibility empowers individual creators, enabling them to execute their textile design visions with ease and efficiency.

The Growing Popularity of DTF Transfers for Promotional Products

DTF transfers are not only revolutionizing apparel design but are also making significant inroads in the production of promotional products. Custom items such as tote bags, caps, and office supplies benefit from the vibrant and durable prints that DTF technology provides. Businesses increasingly recognize the potential of customizable products to strengthen their brand presence and engage their clientele in memorable ways.

With DTF printing, companies can offer unique promotional items that resonate with their target audiences. The ability to print intricate designs on various materials ensures that brands can maintain a cohesive look across their merchandise, enhancing brand recognition. As consumers seek personalized products, DTF transfers stand out as the ideal solution for businesses wanting to make a lasting impression.

Challenges and Considerations in DTF Transfer Usage

Despite the numerous benefits that DTF technology offers, there are challenges that users must navigate. One significant hurdle is the initial setup cost associated with acquiring DTF printers and supplies. This investment can be daunting for smaller enterprises or independent designers without the capital to support such an expense, potentially limiting access to this innovative technology.

Additionally, achieving high-quality prints using DTF transfers requires a specific skill set and understanding of the printing process. As users familiarize themselves with the software and techniques involved, there exists a learning curve that might initially deter some from fully utilizing the technology. Where the rewards can be substantial, the initial steps can be daunting, prompting users to seek proper training to maximize their investment.

Frequently Asked Questions

What are the main advantages of using DTF Transfers in textile design?

DTF Transfers, or Direct-to-Film transfers, offer numerous advantages in textile design. They are highly versatile, working effectively on various fabric types, including cotton and polyester. The quality of prints is exceptional, with high-definition designs that resist peeling and fading. Furthermore, DTF printing is more sustainable compared to traditional methods, reducing textile waste and allowing for on-demand production, which minimizes excess stock.

How does DTF printing technology differ from traditional screen printing?

DTF printing technology differs significantly from traditional screen printing in terms of versatility and setup. While screen printing is cost-effective only for larger runs due to setup costs, DTF Transfers enable businesses to print smaller batches affordably. Additionally, DTF prints can be applied on both dark and light fabrics, whereas screen printing has limitations in color and media, making DTF a more flexible option for apparel customization.

Is DTF Transfers technology suitable for sustainable printing practices?

Yes, DTF Transfers are highly suitable for sustainable printing practices. They generate less waste as they allow for on-demand printing, which reduces the production of surplus items. This eco-friendly approach aligns with the industry’s growing focus on sustainability, making DTF a preferred choice for designers and companies committed to minimizing their environmental footprint in the textile sector.

Can DTF Transfers be applied to all types of fabrics?

Yes, DTF Transfers can be applied to a wide range of fabrics, including both cotton and polyester, as well as various blends. This compatibility makes DTF printing a versatile solution for designers, enabling them to explore apparel customization without being limited by fabric restrictions.

What items can be created using DTF Transfers technology?

DTF Transfers technology can be utilized to create a variety of items such as t-shirts, hoodies, and caps, making it ideal for apparel design. Additionally, it can be used for promotional products like tote bags and office supplies, as well as craft projects, providing endless possibilities for personalization and creativity.

What should beginners know about the setup and application of DTF Transfers?

Beginners interested in DTF Transfers should be aware that while the technology offers significant benefits, there may be an initial setup cost for purchasing DTF printers and materials. Understanding the printing process may require some training, as achieving high-quality prints depends on proper application techniques. It’s important to familiarize oneself with the equipment and software to fully leverage DTF technology for effective and durable designs.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | DTF transfers involve printing designs onto a special film that is transferred onto fabric using heat, resulting in vibrant, long-lasting prints. |

| Benefits of DTF Transfers | 1. Versatility: Suitable for various fabrics. 2. Quality of Print: Durable and high-definition. 3. Sustainability and Low Waste: Reduces textile waste. 4. Cost-Effectiveness: Economical for small orders. |

| Common Applications | Used in apparel design, promotional products, and crafts, allowing for personalized creations. |

| Recent Developments in DTF Technology | Focus on sustainability, technological advancements, user-friendly platforms, and emerging services enhance adoption and innovation in the market. |

| Challenges and Considerations | Initial setup costs, a learning curve for effective use, and potential durability issues if applied incorrectly. |

Summary

DTF Transfers mark a significant evolution in textile design, seamlessly blending innovative printing techniques with sustainability. This groundbreaking technology not only enables intricate and vibrant designs on a variety of fabric types but also promotes eco-friendly practices by minimizing waste. As more designers and businesses adopt DTF Transfers, we can expect to see a shift towards more sustainable production methods that resonate with today’s environmentally conscious consumers. Embracing DTF Transfers paves the way for endless creative possibilities while addressing the industry’s challenges, ultimately transforming the landscape of textile design for the better.