In the ever-evolving world of textile printing, DTF transfers, or Direct to Film transfers, have emerged as a transformative technology that is reshaping the industry. This innovative method allows for exceptional customization and versatility, making it ideal for businesses and individuals alike who want to create unique apparel. DTF printing stands out for its efficiency and quality, enabling vibrant designs to be printed directly onto a film and then transferred to various fabrics. This introduction to DTF transfer technology will delve into how it works, recent advancements, and why it is becoming a favored choice in custom apparel printing and textile decoration. With a growing demand for personalized products, understanding DTF transfers is essential for anyone looking to leverage the latest in heat transfer technology.

DTF transfers, also known as Direct to Film printing, represent a breakthrough in the realm of custom apparel printing and textile decoration. This method simplifies the process of transferring intricate designs onto garments by printing on a special film and utilizing heat transfer mechanisms. With its ability to cater to a wide range of fabrics, DTF technology has garnered attention for its flexibility and high-quality results. As we explore this advanced printing technique, it is crucial to understand its various applications and the recent innovations that have made it a go-to solution for businesses aiming to provide unique, customized offerings. As consumer demand for personalized items continues to surge, the role of heat transfer technology like DTF becomes increasingly vital in the competitive apparel market.

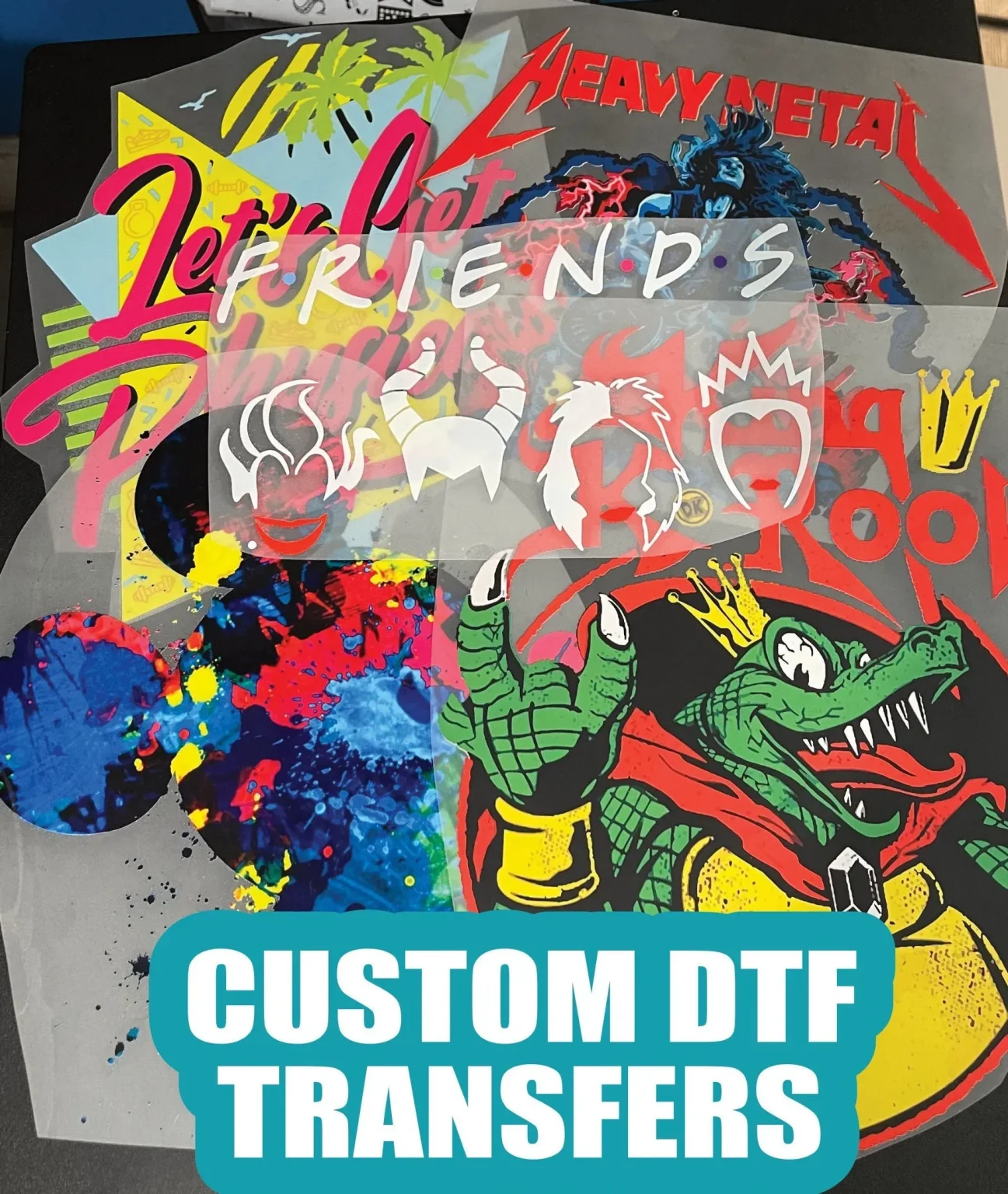

Exploring the Benefits of DTF Transfers

DTF transfers offer an array of benefits that make them a popular choice among custom apparel decorators. One of the most notable advantages is the ability to print intricate designs with high resolution. This means that even the most detailed graphics can be accurately replicated, making DTF ideal for designs such as logos, artwork, and photographs. Moreover, DTF printing is adaptable to various materials including cotton, polyester, and blends, broadening the scope for creative expression in textile decoration.

Additionally, DTF transfers provide exceptional durability. Once applied through heat transfer technology, these prints can withstand multiple washes without fading or peeling. This longevity is particularly advantageous for businesses looking to offer high-quality items that can endure regular wear. The vibrant colors achieved through DTF printing illuminate the garments, enhancing the overall appeal and satisfaction for customers.

How DTF Transfers Compare to Traditional Printing Methods

When examining DTF transfers alongside traditional printing methods, such as screen printing and Direct to Garment (DTG) technology, several clear distinctions emerge. Unlike screen printing, which can be cost-prohibitive for small orders due to setup costs, DTF printing allows for more affordable small batch production. This is especially beneficial for startups or individuals looking to create personalized apparel without investing heavily in equipment.

Furthermore, DTF has a significant advantage over DTG in terms of substrate versatility. While DTG prints directly onto garments and often requires pretreatment, DTF transfers can be applied to an extensive range of materials without the need for preparation. This flexibility helps expand business opportunities, inviting decorators to venture into various markets—from fashion to promotional items—without being limited by equipment specifications.

The Growing Demand for DTF Printing in the Market

The market for DTF printing is witnessing a remarkable surge, driven by the increasing desire for custom apparel among consumers. As individuals seek unique products that reflect their personal styles, innovators in the textile decoration industry are responding with diverse customization options provided by DTF transfers. Reports indicate that this growth is expected to continue, with more businesses entering the market to meet consumer demands for individuality.

Moreover, the rise of e-commerce has contributed significantly to this trend. Online platforms allow consumers to easily access customized products from anywhere, bolstering the DTF printing sector. With brands leveraging DTF technology for fashion and promotional items alike, the versatility of this printing method is propelling both small and large businesses towards increased profitability.

Understanding the Technical Aspects of DTF Transfers

DTF printing merges several sophisticated components, including unique ink formulations and specialized transfer films to achieve professional-quality results. The process begins with printing custom designs onto a specific type of transfer film. This film is then coated with an adhesive powder, which plays a crucial role in securing the design onto fabrics during the heat transfer stage. The utilization of innovative inks enhances color vibrancy and ensures that the finished product can withstand the rigors of daily use.

Learning the technicalities associated with DTF transfers is vital for achieving optimal results. As users gain familiarity with their printer settings and adhesive applications, they discover how to manipulate various elements to improve print quality further. Resources and training that cover these technical aspects are becoming increasingly available, empowering individuals to master DTF technology effectively.

Addressing Common Challenges in DTF Printing

Despite the numerous advantages presented by DTF transfers, users often encounter several challenges, particularly during the initial stages of adoption. The learning curve associated with mastering the setup and darkroom conditions can be steep. New users might face frustrations related to print quality or adhesive issues if they are not adequately trained or informed about the nuances of the process.

However, the growing community of DTF users has led to enhanced resources such as online tutorials and expert workshops. These platforms offer vital insights into troubleshooting common issues. By sharing experiences and solutions, users can overcome initial obstacles and fully embrace the capabilities of DTF printing, ultimately leading to professional-quality custom apparel.

Future Innovations in DTF Technology

As the DTF transfer technology continues to evolve, future innovations promise to enhance both efficiency and print quality. Manufacturers are increasingly investing in research and development to improve ink formulations that not only deliver vibrant prints but are also environmentally friendly. This shift towards sustainable practices is becoming a significant factor in the production process, as businesses aim to reduce their carbon footprint while maintaining high-quality output.

Additionally, ongoing technological advancements in printing machinery are set to revolutionize the DTF printing process further. The introduction of high-speed printers capable of handling larger volumes while ensuring precision will cater to businesses aiming for scalability without compromising on detail and durability. As these innovations take shape, they will undoubtedly contribute to the already bright future of custom apparel printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, involve printing custom designs onto a transfer film using specialized DTF printing methods. The design is then coated with an adhesive powder and heat-pressed onto the fabric. This process creates vibrant and durable prints that work well on various materials, making it an effective choice for custom apparel printing.

What materials can be used with DTF printing technology?

DTF printing technology is versatile and can be used on a wide range of materials including cotton, polyester, leather, and blends. This adaptability makes DTF Transfers a popular choice for textile decoration in custom clothing and promotional items.

How does DTF Transfers compare with other custom printing methods?

Compared to other methods like Direct to Garment (DTG) printing and traditional screen printing, DTF Transfers offer unique advantages such as compatibility with various materials, efficient handling of smaller batch sizes, and generally lower initial equipment costs. Unlike DTG, DTF does not require pretreatment of garments, simplifying the printing process.

What are the recent advancements in DTF printing technology?

Recent advancements in DTF printing include improved ink formulations and adhesive powders that enhance durability and wash resistance. The introduction of eco-friendly inks and high-resolution printers has also made DTF Transfers more accessible, allowing for intricate designs and professional-quality results in custom apparel printing.

Are there training resources available for learning DTF Transfers?

Yes, as DTF printing technology grows in popularity, many suppliers and industry experts offer training resources. Online courses and tutorial videos on platforms such as YouTube help beginners learn the intricacies of DTF Transfers, making it easier to troubleshoot common challenges and improve skills in custom apparel printing.

What challenges might I face when using DTF Transfers?

While DTF Transfers offer many benefits, users often encounter a learning curve regarding setup and troubleshooting, particularly if they are new to DTF printing technology. Achieving optimal printing results requires practice, familiarity with the materials used, and an understanding of the heat transfer process.

| Key Point | Description |

|---|---|

| Introduction | DTF Transfers are emerging as a high-quality, versatile textile printing technology. |

| Overview | DTF involves printing designs onto a film and applying them to fabric via heat, suitable for various materials. |

| Technology Advancements | Improved inks and adhesive powders are enhancing the quality and eco-friendliness of DTF prints. |

| Market Growth | Increasing demand for personalized apparel drives the global market for DTF transfers. |

| Training Resources | Online courses and tutorials are becoming available to assist beginners in mastering DTF technology. |

| Comparison with Other Methods | DTF offers unique advantages over DTG and screen printing, including cost-effectiveness and flexibility. |

| Challenges | Users might face a learning curve in setup and process but can find comprehensive resources to help. |

Summary

DTF transfers are revolutionizing the world of custom apparel printing by offering an innovative approach to textile decoration. This technology not only enhances creativity and personalization for consumers but also provides businesses with a cost-effective solution for diverse applications. As advancements continue to emerge in DTF techniques, along with a growing range of training resources, more individuals and companies can tap into this dynamic printing method. The future of DTF transfers looks promising, paving the way for unique, custom-designed products that cater to modern consumer demands.