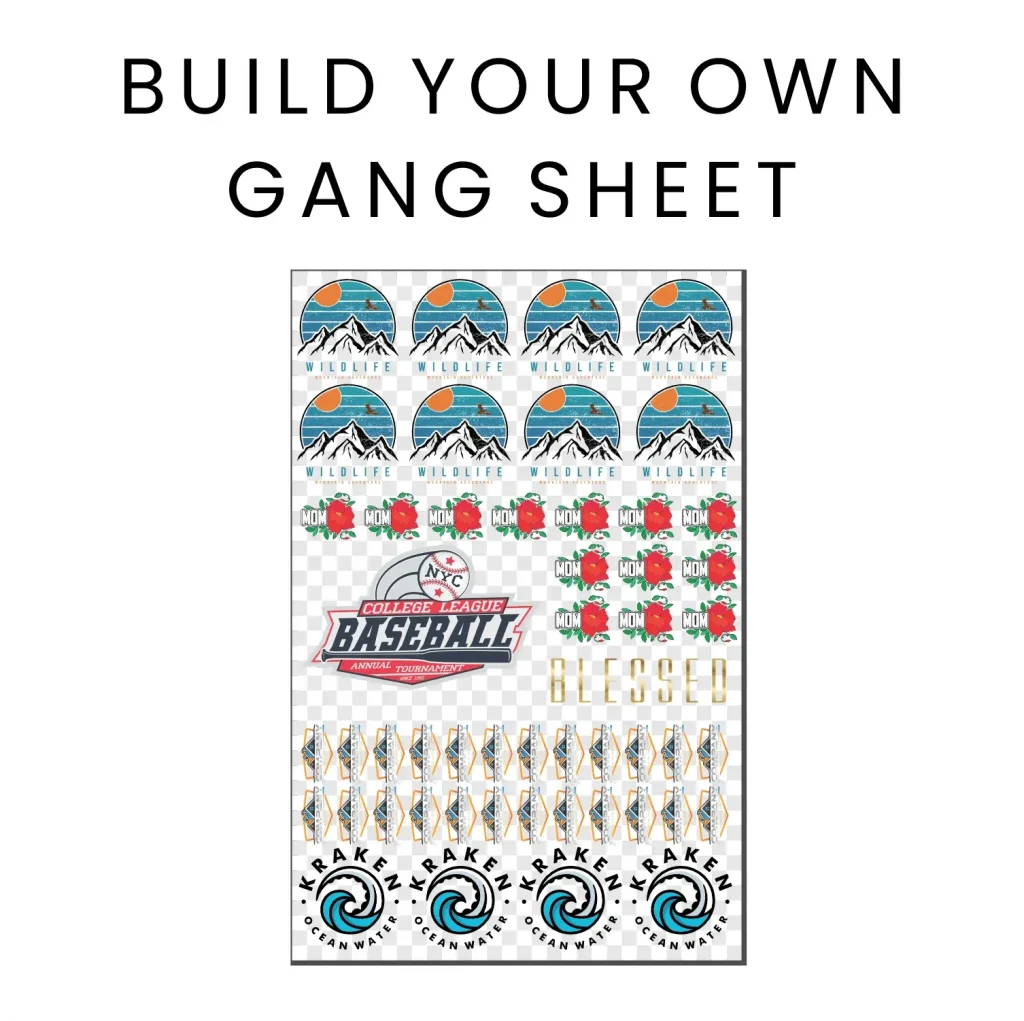

The DTF Gangsheet Builder is an essential tool for any custom printing enthusiast looking to elevate their Direct to Film (DTF) printing game. By utilizing this innovation, designers can optimize their artwork layouts effectively, ensuring they maximize material use while minimizing waste. DTF printing tips featuring the Gangsheet Builder enable users to create vibrant, high-resolution prints that stand out. In this exploration, we will delve into strategies for printing design optimization, helping you master the art of gangsheet printing. These direct to film tips are geared towards enhancing your creative output, making your designs resonate with your audience.

When it comes to custom garment printing, the ability to optimize designs is crucial for producing stunning results. The DTF Gangsheet Builder serves as a powerful asset for enhancing artwork arrangements and reducing excess material. This innovative tool streamlines the gangsheet printing process, ensuring that every element of your design is perfectly placed for maximum impact. By implementing efficient workflows and best practices, you can achieve impressive print quality while saving on costs. Understanding the nuances of direct to film techniques will empower you to create captivating visuals that effectively connect with your target market.

Understanding DTF Printing Basics

Direct to Film (DTF) printing is revolutionizing the custom printing industry with its efficient and high-quality output. This innovative technique involves printing vibrant designs onto a special film which can then be transferred onto various fabrics. One of the key advantages of DTF printing is its ability to produce intricate details and full-color images, making it ideal for creating stunning apparel and merchandise. In this section, we will delve deeper into the core principles of DTF printing, emphasizing its unique characteristics and benefits for designers.

DTF printing serves as a versatile solution across multiple industries, from fashion to promotional items. Unlike traditional printing techniques, DTF allows for better color accuracy and design fidelity, as the ink bonds with the transfer film before being applied to the surface. This method not only reduces ink consumption but also enhances the overall durability and washability of the final product. Understanding these fundamentals is crucial for applying effective printing strategies, especially when utilizing the DTF Gangsheet Builder for optimized designs.

Effective Design Size and Placement Strategies

When working with the DTF Gangsheet Builder, it is essential to carefully consider both the size and placement of your designs on the gang sheet. The optimal arrangement can significantly impact material usage and production costs. To maximize efficiency, designers should measure their gang sheet dimensions and place designs strategically to utilize every available inch. For example, clustering smaller designs together can minimize waste and enhance the overall output of the production run.

Additionally, it is vital to maintain clear margins between designs to prevent any loss during the cutting and transfer process. This practice not only ensures that each design is preserved but also creates a neater finish when applied to the chosen fabric. By optimizing design size and placement, you can achieve a seamless workflow and an engaging visual impact, ultimately improving the effectiveness of your DTF prints.

Color Management Tips for DTF Printing

Color plays a critical role in the outcome of DTF printed materials, making effective color management essential. Utilizing correct color profiles is one of the first steps to ensure that colors appear accurately on the final product. Designers should convert their RGB color schemes to CMYK as part of the preparation process. This conversion helps in maintaining color consistency across various media and prevents discrepancies that might occur during printing.

Additionally, performing test prints can be invaluable for calibrating colors and ensuring that your printing machine produces the shades you’ve envisioned. Running preliminary tests will allow you to make necessary adjustments to the inks or settings that can affect color output, ensuring successful final prints. By prioritizing color management techniques, you can optimize your designs and enhance their visual appeal, thereby creating prints that truly resonate with audiences.

Maintaining High Resolution and Quality in Designs

The quality of prints in DTF printing is heavily influenced by the resolution of the designs being used. To guarantee the best results, maintaining a minimum resolution of 300 DPI (dots per inch) is advisable. This ensures that every detail of the design is captured crisply and clearly when transferred onto the fabric. High-resolution files contribute significantly to the overall professional look of the printed item, making it essential for designers to pay close attention to this aspect.

Moreover, simplifying vector files can reduce processing times and prevent errors during printing. Complex designs can often lead to longer processing durations and potential mishaps in the unrolling or application of the transfer. By keeping designs streamlined and focusing on high-quality output, you improve not just the aesthetic outcome but also the efficiency of your DTF printing process.

Utilizing Transparent Backgrounds in Artwork

In DTF printing, using transparent backgrounds for your designs can yield multiple advantages. Firstly, it significantly conserves ink by preventing unnecessary coverage in non-visible areas, which is especially beneficial when creating elaborate designs. This practice not only lowers printing costs but also enhances the overall appearance of the garments by allowing the fabric to interact seamlessly with the design.

Moreover, transparent backgrounds contribute to a cleaner and more professional finish. When applied to textiles, this approach ensures that the garment’s fabric texture melds beautifully with the printed artwork, creating a cohesive and visually appealing look. Embracing transparency in your designs is a simple yet effective way to elevate the quality and professionalism of your DTF printed products.

Selecting the Right File Formats for DTF Printing

Choosing the appropriate file format is an essential step in the DTF printing process. Formats such as PNG and TIFF are highly recommended due to their capacity to support transparency and maintain high image quality. Unlike JPEGs, which often compress images and introduce visual artifacts, these formats ensure that your designs appear sharp and faithful to the original artwork, minimizing any loss of detail during the printing process.

Furthermore, it’s imperative to confirm the compatibility of your selected file formats with your printing software. Some formats may not interact properly with the specialized software used in DTF printing, leading to complications down the line. By opting for the right formats and ensuring their suitability, you set the foundation for successful and high-quality prints.

Frequently Asked Questions

What are the best DTF printing tips for optimizing designs with the DTF Gangsheet Builder?

To optimize designs with the DTF Gangsheet Builder, focus on appropriate design size and placement, utilize effective color management by converting RGB to CMYK, maintain high resolution (at least 300 DPI), use transparent backgrounds, select the right file formats (preferably PNG or TIFF), and organize your layers wisely for smooth printing.

How does the DTF Gangsheet Builder enhance gangsheet printing efficiency?

The DTF Gangsheet Builder enhances gangsheet printing efficiency by allowing users to optimize the layout of multiple designs on a single sheet. This maximizes material usage, minimizes waste, and reduces overall printing costs while ensuring each element is properly spaced and easy to transfer.

What is the importance of maintaining high resolution in designs when using DTF Gangsheet Builder?

Maintaining high resolution (at least 300 DPI) in designs is crucial when using the DTF Gangsheet Builder, as it ensures sharp, clear prints that transfer well onto fabric. High-quality designs improve the final product’s professional appearance and color accuracy.

Can you explain how to manage colors effectively in DTF printing with the Gangsheet Builder?

To manage colors effectively in DTF printing with the Gangsheet Builder, use calibrated color profiles (convert RGB to CMYK), conduct test prints to ensure color accuracy, and account for the limitations of your printer and inks to achieve cohesive and vibrant results.

What are the recommended file formats for designs in the DTF Gangsheet Builder?

Recommended file formats for designs in the DTF Gangsheet Builder include PNG and TIFF, as they support transparency and maintain higher image quality compared to JPEGs, which can lead to artifacts due to compression.

How can testing and prototyping improve DTF printing outcomes with the Gangsheet Builder?

Conducting testing and prototyping with the DTF Gangsheet Builder allows you to visualize the final product before full production. This process helps identify any alignment, color, or clarity issues, enabling adjustments that ensure optimal final prints.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A printing method involving direct transfer of designs onto surfaces using special film, offering vibrant colors and versatility. |

| Design Size and Placement | Measure dimensions, utilize margin guidelines, and optimize layout to maximize paper usage and minimize waste. |

| Manage Your Colors Effectively | Use CMYK profiles, perform test prints for calibration to achieve accurate color reproduction. |

| Maintain High Resolution and Quality | Ensure designs are at least 300 DPI; optimize vector files for quality and processing efficiency. |

| Use Transparent Backgrounds | Saves ink and creates a professional appearance, blending fabric and design elements seamlessly. |

| Select the Right File Formats | Choose PNG or TIFF formats for high quality and transparency compatibility with DTF software. |

| Organize Your Layers Wisely | Manage colors on separate layers and use descriptive names to enhance workflow during editing. |

| Conduct Testing and Prototyping | Perform test prints to visualize results and make necessary adjustments before full production. |

| Familiarize Yourself with Machine Settings | Adjust printer settings for optimal performance and stay updated on new features from manufacturers. |

Summary

DTF Gangsheet Builder is a powerful tool that optimizes the direct to film printing process, enabling designers to enhance their artwork layout effectively. By focusing on critical elements such as design size, color management, resolution, and layer organization, users can achieve remarkable print quality while minimizing material waste. Proper testing and familiarity with machine settings are also vital for flawless production. Embracing these best practices not only elevates the quality of prints but also efficiently satisfies customer demands, setting the stage for success in the custom printing industry.