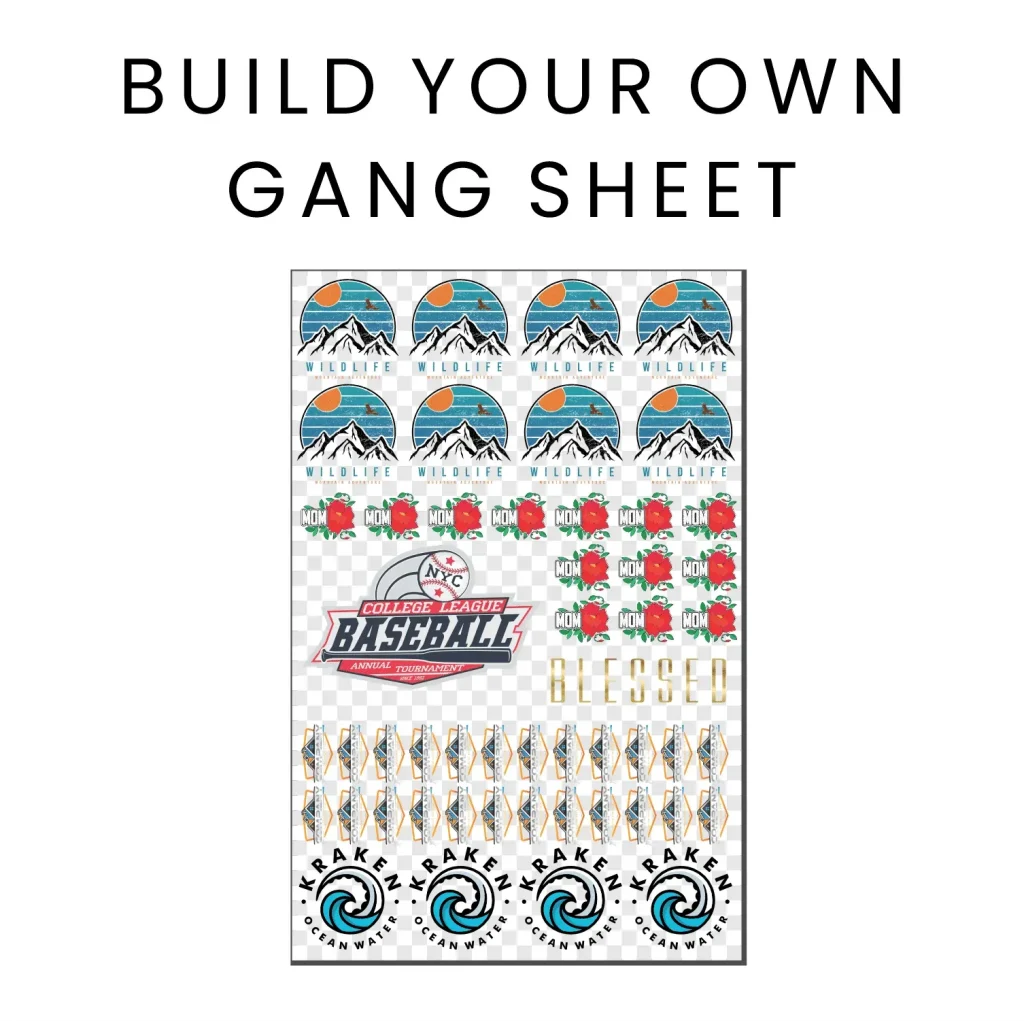

The DTF Gangsheet Builder is a revolutionary tool in the realm of custom apparel printing, designed to enhance the Direct to Film (DTF) printing process. This innovative software allows users to effectively manage multiple designs on a single sheet, ensuring optimal use of materials—a crucial step for anyone looking to reduce costs without compromising quality. Whether you’re exploring how to use DTF Gangsheet for the first time or seeking expert DTF printing tips, mastering this builder is vital for your workflow. By employing gangsheet layout techniques, you can maximize space and streamline your printing efforts, resulting in stunning designs that adhere perfectly to various fabrics. The DTF Gangsheet Builder stands as an indispensable asset for both beginners and seasoned professionals in the competitive world of custom apparel.

In the landscape of custom garment creation, various techniques and tools are available to optimize the printing experience. Among these, software solutions like the DTF Gangsheet Builder facilitate the arrangement of designs onto a singular film sheet, making it easier to manage multiple projects efficiently. This approach not only enhances the efficacy of the Direct to Film printing method but also opens up avenues for broader creative expression in apparel design. Understanding alternative solutions for design layout and exploring effective applications can significantly boost productivity. As the industry continues to innovate, embracing these advanced systems will undoubtedly lead to superior results and greater customer satisfaction.

How to Use DTF Gangsheet for Maximum Efficiency

Using the DTF Gangsheet Builder effectively is pivotal for those looking to maximize their productivity in custom apparel printing. Start by loading your artwork into the software, ensuring that each design is scalable and optimized for print. This allows you to experiment with various layouts before committing to a final print. By carefully arranging your designs, you can fit more images onto a single gangsheet, ensuring that you make the most of your printing materials while minimizing waste. This not only reduces production costs but also helps maintain a steady workflow.

In addition to layout efficiency, the DTF Gangsheet Builder facilitates easier tracking of multiple designs, enabling users to manage their projects more effectively. Whether you’re looking to print a large batch of T-shirts or create a limited run of specialty items, having all of your designs in one place can streamline the entire printing process. By leveraging these gangsheet layout techniques, printers can focus more on their creative designs rather than on logistics, leading to faster turnaround times and satisfied customers.

Essential DTF Printing Tips for Beginners

For those new to Direct to Film printing, understanding the essentials can significantly improve your results. Start by using high-resolution images, as they will yield clearer and more vibrant prints. Explore different paper types and film for your DTF projects, as some may work better for specific designs or fabrics. Additionally, ensure your printer settings are tailored to DTF printing specifications to avoid issues like ink bleeding or poor adhesion.

Furthermore, keeping your workspace organized and clean during the printing process is crucial. Simple practices, like regularly checking your prints and ensuring your materials are in good condition, can help avoid costly mistakes. Engaging with online communities or forums dedicated to DTF printing can provide invaluable insights and tips from fellow printers, helping you navigate the learning curve more effectively.

Understanding Gangsheet Layout Techniques

Optimal gangsheet layout techniques can make a significant difference in the efficiency and quality of your DTF prints. By strategically arranging designs to minimize space and material usage, you can effectively enhance your production capabilities. Consider grouping similar colors together to reduce the risk of color bleeding, a common challenge in DTF printing. Utilizing templates offered by many DTF Gangsheet Builders can also simplify this process, allowing you to focus on creativity rather than technical layout challenges.

Moreover, experimenting with layout configurations is encouraged. As you familiarize yourself with the capabilities of the DTF Gangsheet Builder, you’ll discover various arrangements that can yield both aesthetic variety and production efficiency. Staying agile in your layout strategies can lead to discovering the most effective use of your film, ultimately enhancing both your output and your creative expression in custom apparel design.

The Importance of Quality Control in DTF Printing

Quality control is a crucial aspect of the DTF printing process that shouldn’t be overlooked. Implementing steps to ensure each print batch meets high-quality standards can significantly impact your business reputation. This involves conducting test prints to check color accuracy, alignment, and overall design integrity. Identifying potential issues before running a full production can save time, resources, and frustration.

Additionally, establishing a routine for quality checks after the application of adhesive and heat pressing procedures strengthens the final product’s durability. Checking for issues like poor adhesion or fading helps maintain consistent results, ensuring customer satisfaction. As you refine your quality control processes, you’ll find that a strong focus on detail and diligence will differentiate your custom apparel printing operation in a competitive market.

DTF Printing Troubleshooting: Common Issues and Solutions

In any printing process, troubleshooting common issues is essential, especially when working with DTF printing. Problems such as ink bleeding, poor adhesion, and blurry prints can significantly affect the final output. It’s crucial to understand the typical causes behind these problems. For instance, ink bleeding can often be resolved by rearranging designs to allow for more space between them on the gangsheet, while blurry prints generally indicate that the artwork resolution needs to be revisited before printing.

Another common issue is improper heat press settings, which can lead to adhesion problems. Always ensure you follow specific temperature and pressure guidelines for your materials and adhesive. Keeping a comprehensive troubleshooting guide at hand can assist in quickly resolving issues, leading to better print quality and increased confidence for both novices and seasoned DTF printers.

Future Trends in Custom Apparel and DTF Technology

The landscape of custom apparel printing is continuously evolving, with DTF technology aligning perfectly with future trends in efficient and eco-friendly printing solutions. As sustainability becomes a significant focus in manufacturing, the DTF printing process offers advantages such as reduced waste and the ability to print on a variety of fabric types without compromising quality. Innovations in ink formulations and transfer materials are likely to enhance the already impressive capabilities of DTF technology, enabling even greater customization options.

Moreover, with advancements in software tools like the DTF Gangsheet Builder, printers will find it easier to create intricate designs that cater to consumer preferences. The shift toward personalized apparel is gaining momentum, and those adapting to these technological advancements will likely be at the forefront of the custom apparel industry. Embracing new techniques and continuously improving your skills will ensure you stay competitive in the marketplace.

Frequently Asked Questions

How to use DTF Gangsheet Builder effectively?

To use the DTF Gangsheet Builder effectively, start by preparing high-resolution artwork in the correct format. Next, choose the right gangsheet size based on your DTF printer’s capabilities. Use the drag-and-drop feature to layout your designs efficiently while preventing ink bleeding. Remember to test print for color accuracy and ensure proper adhesive application before heat pressing.

What are some DTF printing tips for beginners?

For beginners in DTF printing, familiarize yourself with the gangsheet layout techniques. Ensure your artwork is prepared in high resolution and the correct formats. Always run a test print to check alignment and color accuracy before the final print. Focus on applying the right amount of adhesive powder to avoid issues during the heat press. Through practice, you’ll improve your skills quickly.

What is the role of a DTF Gangsheet Builder in custom apparel printing?

The DTF Gangsheet Builder plays a crucial role in custom apparel printing by allowing users to efficiently arrange multiple designs onto a single sheet of film. This enhances material usage, minimizes waste, and streamlines the printing workflow, leading to cost savings and improved production efficiency.

What are the best practices for gangsheet layout techniques?

Best practices for gangsheet layout techniques include using high-resolution images, organizing designs by color to prevent ink bleeding, and maximizing the space on the sheet. It’s also helpful to utilize the features of the DTF Gangsheet Builder to adjust the size and arrangement of designs for optimal placement.

What are common issues when using the DTF Gangsheet Builder, and how to troubleshoot them?

Common issues include ink bleeding, poor adhesion, and blurry prints. To troubleshoot, ensure designs are spaced correctly on the gangsheet, check heat press settings for proper adhesive application, and verify that your artwork is high-resolution. Always run test prints to catch any issues early.

How can I enhance my skills in DTF printing using the Gangsheet Builder?

Enhancing your DTF printing skills using the Gangsheet Builder involves practicing different layout techniques, experimenting with design placements, and staying updated with community tips and tutorials. Consistent practice and learning from feedback will help you improve your efficiency and output quality.

| Key Points | Details |

|---|---|

| Introduction | DTF technology is a game-changer for custom apparel printing, with the DTF Gangsheet Builder streamlining the process for all experience levels. |

| Understanding DTF Printing | DTF printing allows for vibrant images printed on transfer film for various fabrics. Its quality and versatility are appealing to businesses. |

| What is a DTF Gangsheet Builder? | A tool that arranges designs onto a single sheet or roll of film, optimizing material use and is crucial for both small and large runs. |

| Advantages of Using a DTF Gangsheet Builder | Minimizes waste, enhances time efficiency, and assures quality control during the printing process. |

| Step-by-Step Usage | Prepare artwork, select gangsheet size, layout designs, test print, apply adhesive, heat press, and cure the print. |

| Troubleshooting | Common printing issues include ink bleeding, poor adhesion, and blurry prints, with solutions provided. |

Summary

The DTF Gangsheet Builder is an essential tool for anyone involved in the world of custom apparel printing. This software not only simplifies the organization of multiple designs but also maximizes efficiency, reducing waste and saving costs in the printing process. By mastering the DTF Gangsheet Builder, users can significantly enhance their workflow, ensuring high-quality prints that meet their creative vision. Overall, understanding and effectively utilizing the DTF Gangsheet Builder is vital for achieving success in the competitive custom apparel landscape.