The DTF Gangsheet Builder is revolutionizing the way designers approach digital fabric printing, making it an essential tool for creating intricate garment designs. This innovative platform enables users to optimize their gangsheet layout, maximizing efficiency by allowing multiple prints on a single sheet. As interest in heat transfer printing continues to grow, mastering DTF printing tips becomes vital for achieving vibrant and eye-catching results. With the right design software for DTF printing, you can easily manipulate visuals and enhance your apparel project. In this guide, we will explore critical techniques to elevate your printing skill and ensure your designs capture attention in a competitive marketplace.

The DTF Gangsheet Builder, an essential tool for efficient apparel design, is making waves in the realm of heat transfer technology. This system is perfect for artists and entrepreneurs seeking to streamline their digital fabric printing process. By utilizing effective strategies, such as maximizing gangsheet layout and implementing precise printing techniques, you can create visually stunning designs that stand out. The combination of advanced design software for DTF setups and best practices can lead to remarkable outcomes, ensuring products not only please visually but also withstand the test of time. Dive into this exploration of cutting-edge methods and tips to harness the potential of direct-to-film printing, paving the way for your success.

The Benefits of DTF Printing Technology

DTF printing technology has reshaped the textile industry by offering numerous advantages over traditional printing methods. One of the primary benefits is the ability to produce vibrant, high-quality prints without the constraints of fabric and color limitations. This technology supports a wide range of materials, from cotton to polyester and even blends, allowing for creative freedom in apparel design. Additionally, DTF printing ensures excellent durability and longevity of prints, making it an ideal choice for custom apparel that withstands the test of time.

Another significant advantage of DTF printing is its efficiency in production. The process allows for multiple designs to be printed simultaneously on a single gangsheet, which minimizes waste and reduces the overall production time. This feature is particularly appealing to small businesses and independent artists, enabling them to meet customer demands quickly without compromising on quality. With DTF printing, users can achieve stunning results while optimizing their workflow, proving it to be a game-changer in the realm of digital fabric printing.

Mastering the Gangsheet Layout

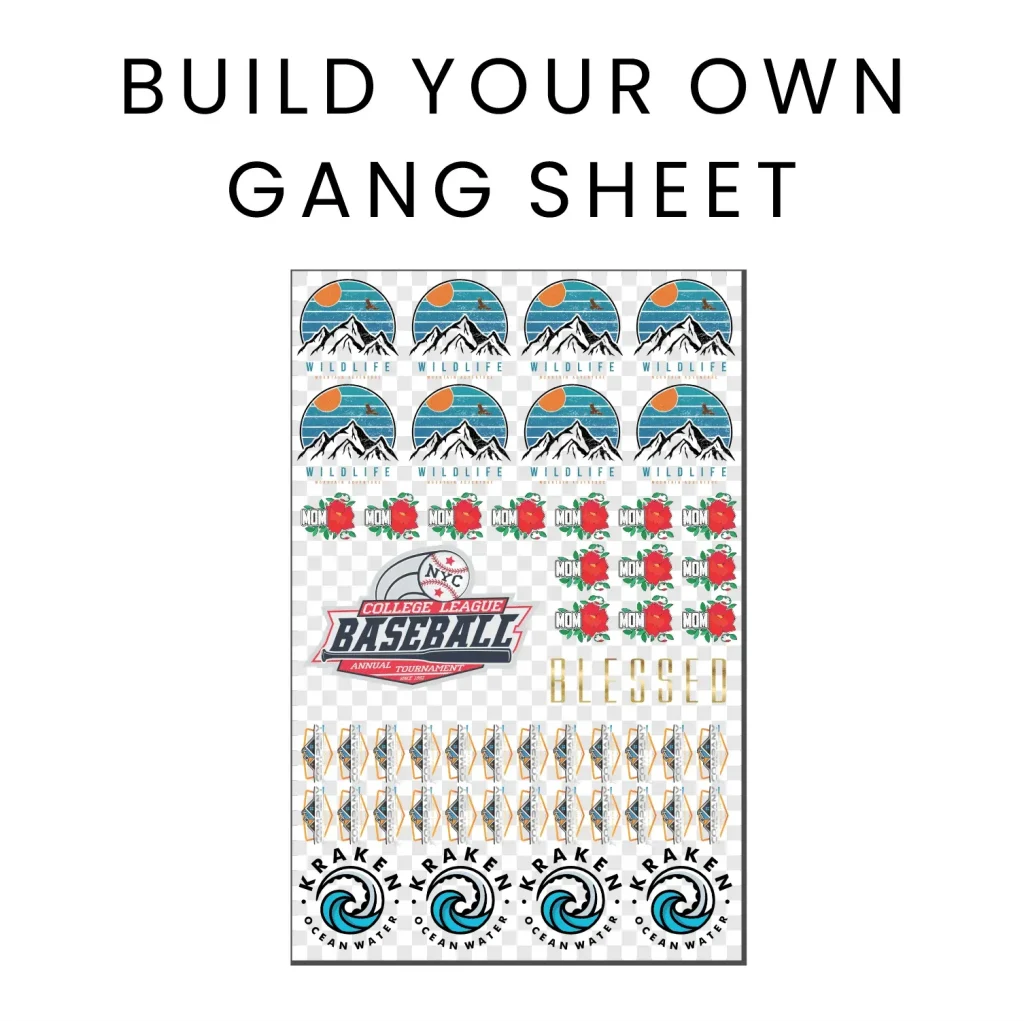

The gangsheet layout is a vital aspect of DTF printing that directly impacts both efficiency and print quality. Organizing designs effectively within the gangsheet can maximize material usage, ultimately lowering production costs. Users should consider arranging their designs in a grid format, which not only optimizes space but also ensures that margins are adequate for cutting and handling post-printing. This careful planning contributes to a streamlined workflow and minimizes wasted products, which is critical in the competitive world of custom apparel.

In addition to practical space optimization, a well-planned gangsheet should aim to balance complex designs with simpler ones. This variety can help in testing different print settings and color profiles in one go. For instance, if some designs require intricate details while others are more straightforward, combining them on a single gangsheet can produce valuable insights about how various prints perform under the same conditions. This strategy enhances the overall learning experience for designers, allowing them to make necessary adjustments before full-scale production.

Choosing the Right Software for DTF Printing

The choice of design software plays a crucial role in the success of DTF printing. Programs like Adobe Illustrator and CorelDRAW are highly recommended because they provide the essential tools for creating and manipulating complex graphics. These platforms enable users to work on designs in high resolution, ensuring that every detail remains crisp and vibrant during the printing process. With advanced vector editing features, these design tools also facilitate easier adjustments and scaling, making them ideal for fine-tuning artwork for DTF gangsheet layouts.

Moreover, compatibility with printing hardware is another vital aspect to consider when selecting design software. Many modern software solutions offer integrated features that assist with color profiling tailored for DTF printing, which is instrumental in achieving consistent results across multiple prints. Utilizing software that supports the creation of ICC profiles or allows direct communication with printing machines can drastically improve the final output quality. Additionally, being proficient in design software not only streamlines the workflow but also opens up new creative possibilities for artists looking to push the boundaries of their designs.

Essential Color Management Techniques

Color management is a quintessential component of successful DTF printing. The intricate process involves ensuring that the colors seen on the computer screen closely match those produced in the final prints. Utilizing the correct color profiles designed specifically for DTF printing significantly aids in maintaining consistency across different batches. For best results, it’s recommended to perform test prints before committing to a full production run, allowing designers to verify that their colors appear as anticipated once applied to fabric.

Beyond just color profiles, employing a calibrated monitor is essential for accurate color representation. Designers need to ensure their screens reflect true colors to make informed decisions while creating. This step minimizes discrepancies caused by varied lighting conditions and monitor settings, ensuring that the digital artwork translates seamlessly to the physical prints. Additionally, keeping a color swatch library can help designers compare and select the right shades effectively, fostering greater creativity and reducing the risk of unexpected results during production.

Selecting Quality Materials for DTF Printing

The quality of materials used in DTF printing can greatly impact the overall outcome of the prints. Selecting the right transfer films and adhesives is essential for achieving desirable results and ensuring long-lasting adhesion on fabrics. Not all transfer films are compatible with every type of fabric; thus, it is crucial to invest in high-quality DTF-specific materials that suit particular textiles such as cotton, polyester, or blends. The right combinations enhance the durability and feel of the prints, ensuring that they stand up to wear and washing over time.

Furthermore, conducting thorough research on material suppliers can be beneficial. Opting for reputable brands often guarantees quality performance across various fabric types. Additionally, keeping track of customer feedback on material performance can guide choices and help identify trends in what works best for specific designs. With adequate attention to material selection, designers can significantly enhance their DTF printing endeavors, achieving results that not only look great but also last long in the competitive market of custom apparel.

Perfecting Heat Press Techniques

Mastering heat press techniques is paramount for successful DTF printing. The application of heat is what allows the prints to adhere properly to fabrics, and getting the temperature and pressure settings right is crucial. Each type of fabric and transfer film has its own specifications, so it’s important to consult manufacturer guidelines to determine the optimal heat settings. Taking the time to experiment with different pressures and temperatures during testing phases can prevent mishaps during production runs, ensuring consistent quality in the final products.

The pressing process should also include attention to timing. Leaving prints under the heat press for too long or not long enough can detrimentally affect the adhesion of the transfers, leading to issues such as peeling or fading. A recommended best practice involves using a timer to manage pressing durations meticulously. Additionally, conditioning the heat press surfaces regularly boosts the effectiveness of adhesion. By understanding and applying precise heat press techniques, designers can significantly enhance the quality of their DTF prints, leading to greater customer satisfaction and a standout product.

Post-Processing Techniques for DTF Success

Post-processing is a critical phase in the DTF printing workflow, as it greatly influences the finish and durability of the final product. After applying the heat transfer and allowing prints to cool, it’s essential to carefully peel away the transfer film. Premature peeling can lead to lifting of the design, compromising not only the print quality but also customer satisfaction. Ensuring that prints are cooled down sufficiently before removal can enhance adhesion, leading to a professional and polished appearance.

Additionally, incorporating techniques such as curing or setting prints can contribute to long-lasting results. Curing involves placing the print in a heated environment for a specified time to ensure that the inks fully bond with the fabric. Some fabric types might require specific post-processing measures to ensure the colors remain vibrant and the designs last. By focusing on effective post-processing methods, producers can significantly improve the longevity and quality of their DTF prints, elevating the overall value of their products in the market.

Frequently Asked Questions

What are the benefits of using a DTF gangsheet builder in digital fabric printing?

Using a DTF gangsheet builder in digital fabric printing increases efficiency by allowing multiple designs to be printed simultaneously, reducing material waste and turnaround time. This is particularly advantageous for businesses looking to maximize production capabilities and maintain high-quality prints.

How do I optimize my gangsheet layout for better DTF printing results?

To optimize your gangsheet layout for DTF printing, organize your designs into a grid pattern with adequate margins for cutting. This strategic layout maximizes material use and enhances printing efficiency, ensuring your designs fit perfectly within the gangsheet space.

What design software is best for creating DTF prints?

The best design software for creating DTF prints includes Adobe Illustrator and CorelDRAW. These programs provide advanced tools for precise graphic creation and manipulation, ensuring your designs maintain high resolution at 300 DPI, crucial for quality prints.

What color management techniques should I use for DTF printing?

Implement accurate color management techniques by using a color profile specifically designed for DTF printing. This ensures consistency across prints and helps achieve expected colors on fabric. Always conduct test prints to validate color accuracy before a full production run.

What should I consider when selecting materials for DTF heat transfer printing?

When selecting materials for DTF heat transfer printing, choose high-quality transfer films and adhesives that are compatible with your target fabrics (like cotton or polyester). Quality materials play a significant role in achieving vibrant prints and ensuring good adhesion.

What should I know about pressing techniques for DTF prints?

Master pressing techniques by researching optimal temperature and pressure settings specific to different materials and transfer films. Proper application is crucial to successful DTF printing, as incorrect settings can lead to print failures and reduced quality.

| Aspect | Details |

|---|---|

| What is DTF Printing? | A revolutionary technology that prints designs on films, which are then transferred to fabric using heat. |

| What is a DTF Gangsheet? | A sheet that can hold multiple designs for efficient printing, saving time and reducing waste. |

| Choosing the Right Design Software | Use software like Adobe Illustrator or CorelDRAW, set at 300 DPI for optimal clarity. |

| Using Accurate Color Management | Employ color profiles for consistency and conduct test prints before full runs. |

| Optimizing Gangsheet Layout | Organize designs in a grid to maximize usage and ensure adequate cutting margins. |

| Selecting Materials Wisely | Choose high-quality transfer films and adhesives suitable for your target fabrics. |

| Mastering Pressing Techniques | Research optimal temperature and pressure settings for different materials. |

| Post-Processing Techniques | Cool garments fully before peeling to avoid poor adhesion and lifting. |

Summary

DTF Gangsheet Builder transforms the art of textile design into a seamless and efficient process, enabling creators to produce stunning outputs with ease. By harnessing the power of Direct-to-Film printing, you not only maximize your workflow efficiency but also enhance the quality of your designs. This guide provides essential insights and practical tips to optimize your designs and printing processes, ensuring your creations stand out in the vibrant world of custom apparel and merchandise.