The DTF Gangsheet Builder stands at the forefront of innovative Direct-to-Film printing technology, revolutionizing the way designs are transferred to textiles. Ideal for those looking to maximize efficiency, this powerful tool allows multiple designs to be combined seamlessly onto a single sheet, significantly reducing waste and cost. With the right DTF printing tips and techniques, users can create striking prints that maintain their quality across different materials. In this article, we will explore essential strategies on how to optimize DTF prints, ensuring vibrant visuals that catch the eye. Dive into the world of gangsheet layout and discover how optimizing your process can elevate your printing projects to new heights.

The DTF Gangsheet Builder, also known as Direct-to-Film design consolidator, is a game changer for businesses and enthusiasts dedicated to high-quality fabric printing. By streamlining the gangsheet layout, users can efficiently combine various prints on a single film, making the most of their materials. This approach drastically reduces resource waste and enhances production efficiency, especially when employing effective DTF printing techniques. As we further elaborate on the methods to improve your print outcomes, you will learn tips to master every aspect of image preparation and application for remarkable results.

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is a powerful tool designed to streamline the DTF printing process. By allowing multiple designs to be printed on a single sheet, this innovative software not only increases efficiency but also significantly reduces material waste. Utilizing this builder, you can maximize the use of your films and lower production costs, which is crucial for businesses aiming to enhance profit margins. Learning how to effectively navigate and utilize the features of the Gangsheet Builder will enable you to produce more prints in less time while maintaining high-quality standards.

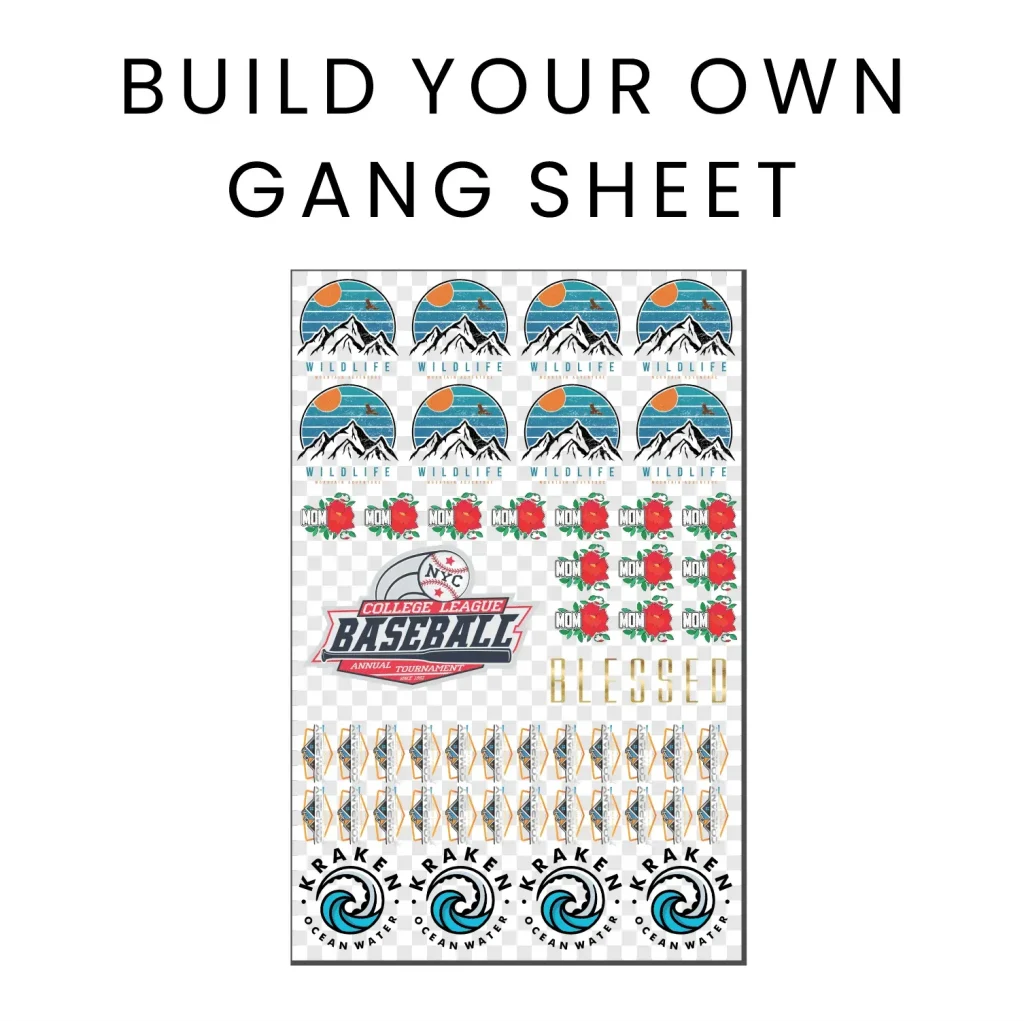

To truly leverage the capabilities of the DTF Gangsheet Builder, it’s essential to focus on the gangsheet layout. Proper arrangement is key; ensuring that all designs fit neatly without overlapping helps to facilitate smoother printing and easier cutting. Additionally, when you optimize the layout, you can create a visually appealing sheet that serves not only functional needs but aesthetic ones as well. By incorporating essential DTF printing techniques, you can cultivate a more efficient workflow, ultimately leading to higher quality outputs.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it enhance the printing process?

The DTF Gangsheet Builder is a tool designed for Direct-to-Film printing that allows users to arrange multiple designs on a single sheet. This not only maximizes material use, minimizing waste, but also streamlines the printing process, enabling faster production without sacrificing quality.

How can I optimize designs using the DTF Gangsheet Builder for better prints?

To optimize your designs using the DTF Gangsheet Builder, ensure that all images are high-resolution and appropriately sized for the layout. Arrange designs to maximize space while maintaining sufficient spacing for easy cutting, ensuring that quality is not compromised in favor of quantity.

What are some key DTF printing tips for successful results with a gangsheet layout?

Key DTF printing tips include preparing high-resolution images, using the correct ICC profiles for color management, and ensuring precise adhesive powder application. Additionally, testing on different fabrics will help you find the ideal material for your designs, resulting in enhanced print quality.

How important is color management when using a DTF Gangsheet Builder?

Color management is critical when using a DTF Gangsheet Builder. Utilizing the correct ICC profiles ensures that your prints maintain accurate color fidelity, resulting in vibrant and consistent outputs that reflect what you see on screen. This attention to detail minimizes discrepancies in color reproduction.

What techniques should I use for adhesive and powder application in DTF printing?

For optimal adhesive and powder application in DTF printing, find a balance in the amount used—too much leads to a rough finish, while too little results in poor adherence. Practicing on scrap materials helps perfect your technique and ensures durable, high-quality prints.

What should I consider when experimenting with different materials for DTF printing?

When experimenting with different materials for DTF printing, consider how each fabric type influences the print’s feel and longevity. Testing on a variety of textiles such as cotton and polyester blends allows you to understand their compatibility with your designs and optimize the final appearance.

| Aspect | Key Points |

|---|---|

| Introduction | DTF technology is revolutionizing printing with vibrant, high-quality prints and resource efficiency. |

| Understanding Gangsheet Layout | Maximize layout efficiency without compromising quality. Proper arrangement allows for easy cutting and application. |

| Image Preparation | Use high-resolution images and appropriate sizing to enhance print quality. Utilize tools like Photoshop for optimal design preparation. |

| Color Management | Use correct ICC profiles for accurate and vibrant colors. Tailored color management is essential for consistency. |

| Adhesive and Powder Application | Balance is key for adhesive powder application to ensure quality adherence and finish. |

| Experimenting with Different Materials | DTF is versatile with various textiles; testing different fabrics can optimize print quality and adhesion. |

| Using Reliable Software and Tools | Updated software enhances the DTF experience; familiarize yourself with features for best results. |

| Post-Printing Curing Techniques | Follow manufacturer guidelines for curing processes to ensure print durability and resistance. |

Summary

The DTF Gangsheet Builder is an essential tool for achieving the best results in DTF printing. By focusing on critical aspects such as high-resolution image preparation, precise gangsheet layout, and effective color management, users can significantly enhance the quality of their prints. Moreover, experimenting with diverse materials and utilizing up-to-date software will further elevate the printing experience. Finally, adhering to recommended adhesive application techniques and curing guidelines ensures durability and vibrancy in prints, solidifying the DTF Gangsheet Builder as a cornerstone in the world of digital textile printing.