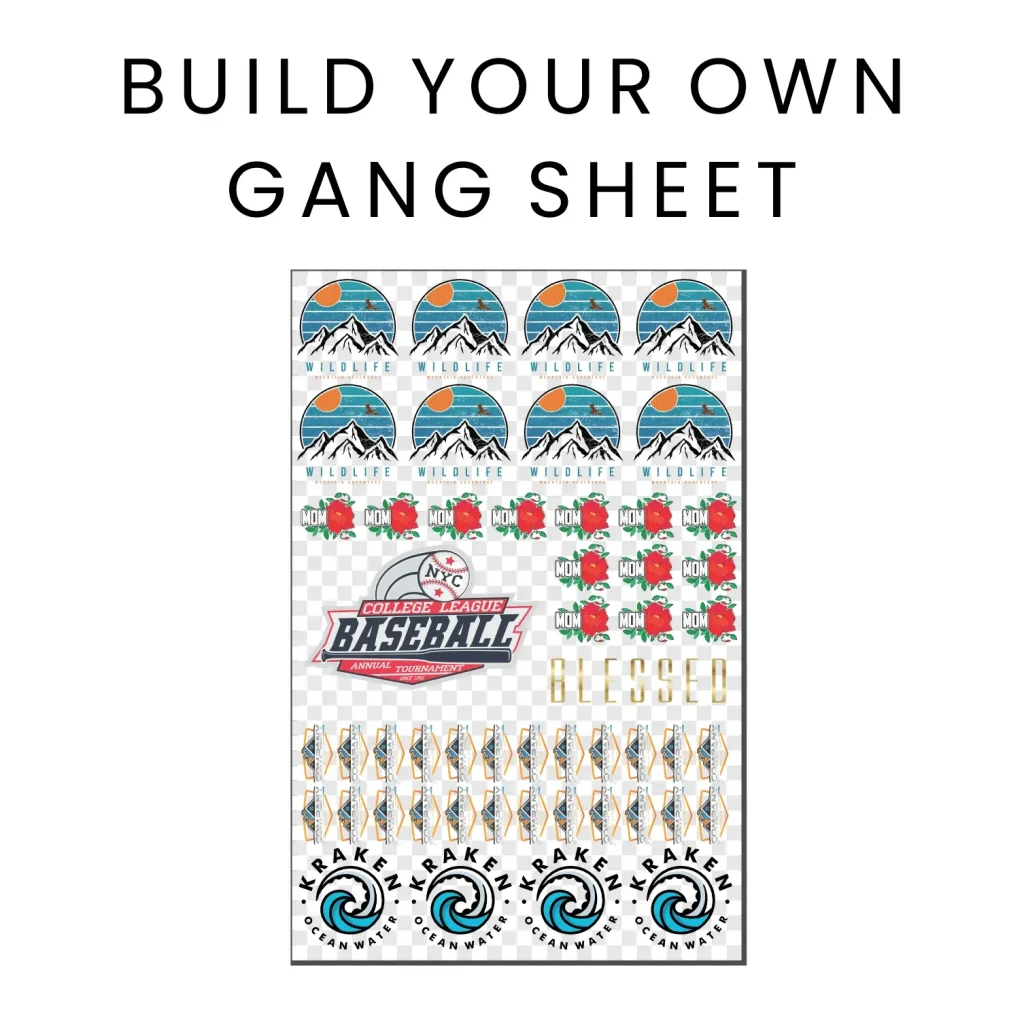

The DTF Gangsheet Builder is revolutionizing the way we think about Direct-to-Film (DTF) printing, a method that has surged in popularity within the textile industry. This innovative tool allows for effective gangsheet printing, enabling users to maximize their design space while reducing material waste. With the right DTF printing tips, designers can create stunning visuals that translate seamlessly onto garments, ensuring vibrant color management and optimized print quality. By mastering the DTF Gangsheet Builder, you can streamline your printing process, saving both time and resources without compromising on the final product. Let’s explore essential strategies to enhance your print design optimization and elevate your DTF projects to new heights.

When discussing Direct-to-Film (DTF) printing, many may refer to it simply as transfer printing or film-based printing; however, the principles behind these processes are essential for achieving remarkable results. The concept of a gangsheet encompasses the technique of consolidating multiple designs onto a single sheet, allowing for efficient production and reduced costs. Utilizing a DTF Gangsheet Builder not only facilitates the arrangement of various artwork but also ensures that users can effectively manage color profiles for stunning outcomes. By understanding the nuances of print design and the intricacies of heat transfer, enthusiasts can unlock the full potential of their printing endeavors. Embracing these alternative terms will broaden your comprehension of the field, highlighting the importance of advanced techniques in achieving superior prints.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing has revolutionized the textile printing landscape, offering unparalleled versatility for producing vivid designs on a range of fabrics. Unlike traditional methods, DTF allows for intricate details and vibrant colors, making it an ideal choice for custom apparel. Understanding the fundamental principles of DTF printing is the first step towards mastering techniques like the DTF gangsheet builder, which optimizes material usage and reduces costs.

At its core, DTF printing involves printing designs on a special film which is then transferred onto the fabric using heat and pressure. A gangsheet enables you to maximize this process by placing multiple designs on a single sheet, leading to time efficiency and reduced ink consumption. As you delve deeper into DTF printing, it becomes essential to refine your skills in utilizing the gangsheet effectively to unlock its full potential.

Tips for Effective Gangsheet Design

Optimizing your gangsheet design is crucial in achieving high-quality results in DTF printing. Start by grouping similar designs together on the sheet, ensuring a balance between aesthetics and production efficiency. This approach not only saves ink but also streamlines the printing process as multiple items can be produced simultaneously. Additionally, maintaining appropriate spacing between your graphics prevents overlaps and misprints, which can detract from the final product’s quality.

Another vital tip is ensuring that each design is appropriately sized for the fabric it will be applied to. Adjusting size can enhance visibility and ensure that intricate details remain intact after heat transfer. As you design your gangsheet, consider the final application—the type of fabric, the colors used, and the overall composition of the designs to create a visually appealing and effective gangsheet.

Mastering Color Management for DTF Printing

Color management plays a pivotal role in DTF printing, as accurate color reproduction can significantly impact the quality of your final prints. Utilizing the correct color profiles tailored to your specific printer and transfer film is essential for achieving vibrant and true-to-life colors. In many cases, mismatched color profiles may result in disappointing prints that fail to meet design expectations. Regular calibration of your printer is also necessary to maintain color consistency across various materials.

To enhance your color management strategy, examine the specific inks you are using. Some inks may require distinct settings or additives to ensure optimal performance, particularly when working with textiles that have differing degrees of absorbency. By thoroughly researching and adapting your color management techniques to meet the needs of your printing projects, you will achieve a higher standard of print quality.

Fine-Tuning DTF Printing Settings

The settings you choose during the DTF printing process can make a substantial impact on the outcome. Experimenting with various printing resolutions can help you strike a balance between speed and quality. Higher resolutions are often necessary for detailed designs, while adjusting the printing speed can prevent common issues like smudging. Fine-tuning these settings ensures you get the best possible results from your printer.

Moreover, the heat transfer settings—temperature, pressure, and time—are critical in achieving strong adhesion of the ink to the fabric. Conducting preliminary test prints with varying heat transfer settings will provide insight into how different materials respond, leading to more consistent and reliable results. Always documenting your findings will help streamline your future printing jobs.

Choosing High-Quality Materials for DTF Printing

Selecting quality materials is fundamental in any successful DTF printing operation. High-quality transfer films and compatible inks are vital for ensuring that your designs adhere properly and remain vibrant over time. The potential pitfalls of using low-grade materials cannot be overstated, as they can compromise both the durability and the visual appeal of your prints.

In addition to the films and inks, it’s essential to consider the type of fabric being used. Different fabrics have unique properties that can significantly influence the print results, including how well they absorb the ink and how they handle heat. Performing tests on various materials will allow you to identify the best combinations, ultimately leading to a more polished and professional final product.

Post-Processing Techniques for Enhanced Print Quality

Post-processing is often overlooked in DTF printing, yet it can significantly contribute to print quality. After your designs are printed, allowing time for proper curing is critical; this step ensures that the films are ready to adhere to the fabric effectively. Skipping curing can lead to poor results, making it essential to integrate this step into your workflow.

In addition to curing, the use of powder adhesives can enhance the ink’s bonding with the fabric. This is particularly useful for materials that require a stronger hold. By implementing these post-processing techniques, you not only improve the quality of your prints but also increase their lifespan, ensuring that your designs remain vibrant and intact for a longer period.

Frequently Asked Questions

What are the best practices for using the DTF Gangsheet Builder in my projects?

To effectively use the DTF Gangsheet Builder, focus on optimizing your design layout by arranging multiple graphics, maintaining appropriate spacing, and sizing each graphic to match the targeted fabric. This ensures efficient printing while maximizing material use.

How can I improve color management when using the DTF Gangsheet Builder?

Improving color management in your DTF Gangsheet Builder starts with using the correct color profiles for your printer and transfer films. Regular calibration of your printer will also help maintain color accuracy, ensuring that your prints achieve true-to-life colors.

What materials do I need for effective DTF gangsheet printing?

For successful DTF gangsheet printing, it’s essential to invest in high-quality transfer films and inks. The choice of fabric also plays a crucial role, as different materials react differently to inks and films, so consider testing various combinations for the best results.

What role do printing settings play in mastering my DTF Gangsheet Builder?

Printing settings are vital in optimizing your DTF Gangsheet Builder. Fine-tune aspects such as resolution and speed based on your design’s intricacy. Additionally, test the heat transfer settings to find the ideal temperature and pressure for maximum adhesion.

How does post-processing affect the quality of prints made with the DTF Gangsheet Builder?

Post-processing techniques like proper curing and the use of powder adhesives significantly enhance print quality. Allowing films to cure thoroughly before application ensures better adhesion, while powder adhesives can improve the bond on fabrics requiring stronger attachment.

Which software is best for managing designs with the DTF Gangsheet Builder?

Using vector graphic software like Adobe Illustrator or CorelDRAW is ideal for managing designs with the DTF Gangsheet Builder. These programs allow for easy layer management and modifications, which can enhance the quality and organization of your print designs.

| Key Point | Description |

|---|---|

| Understanding DTF Gangsheet Printing | A gangsheet contains multiple designs printed together to optimize material and ink usage, which saves costs and time. |

| Optimize Design Layout | Group designs together on a gangsheet with adequate spacing to avoid overlaps and ensure proper sizing for target fabrics. |

| Prioritize Color Management | Select the correct printer profiles and regularly calibrate your printer to ensure accurate color reproduction. |

| Fine-Tune Your Printing Settings | Experiment with print resolutions and speeds, and test heat transfer settings for optimal adhesion and qaulity. |

| Choose Quality Materials | Use high-quality films and inks suited for various fabric types to enhance print durability. |

| Implement Post-Processing Techniques | Ensure proper curing of films and use powder adhesives to improve ink bonding on fabrics. |

| Leverage Software Effectively | Utilize compatible design software with layer management features for improved organization and quality. |

| Maintain Print Area Cleanliness | Regularly clean the workspace and printer, and perform maintenance to prevent issues and ensure quality prints. |

Summary

DTF Gangsheet Builder is crucial for achieving high-quality prints in the textile printing realm. By understanding the foundation of DTF printing and applying effective strategies such as optimizing design layouts, prioritizing color management, and selecting quality materials, you can significantly enhance your printing results. Implement post-processing techniques and leverage compatible software to increase efficiency and print quality. Lastly, maintaining cleanliness helps ensure your equipment functions well, giving you the best chance for success. With these tips, you’re well on your way to mastering DTF printing!