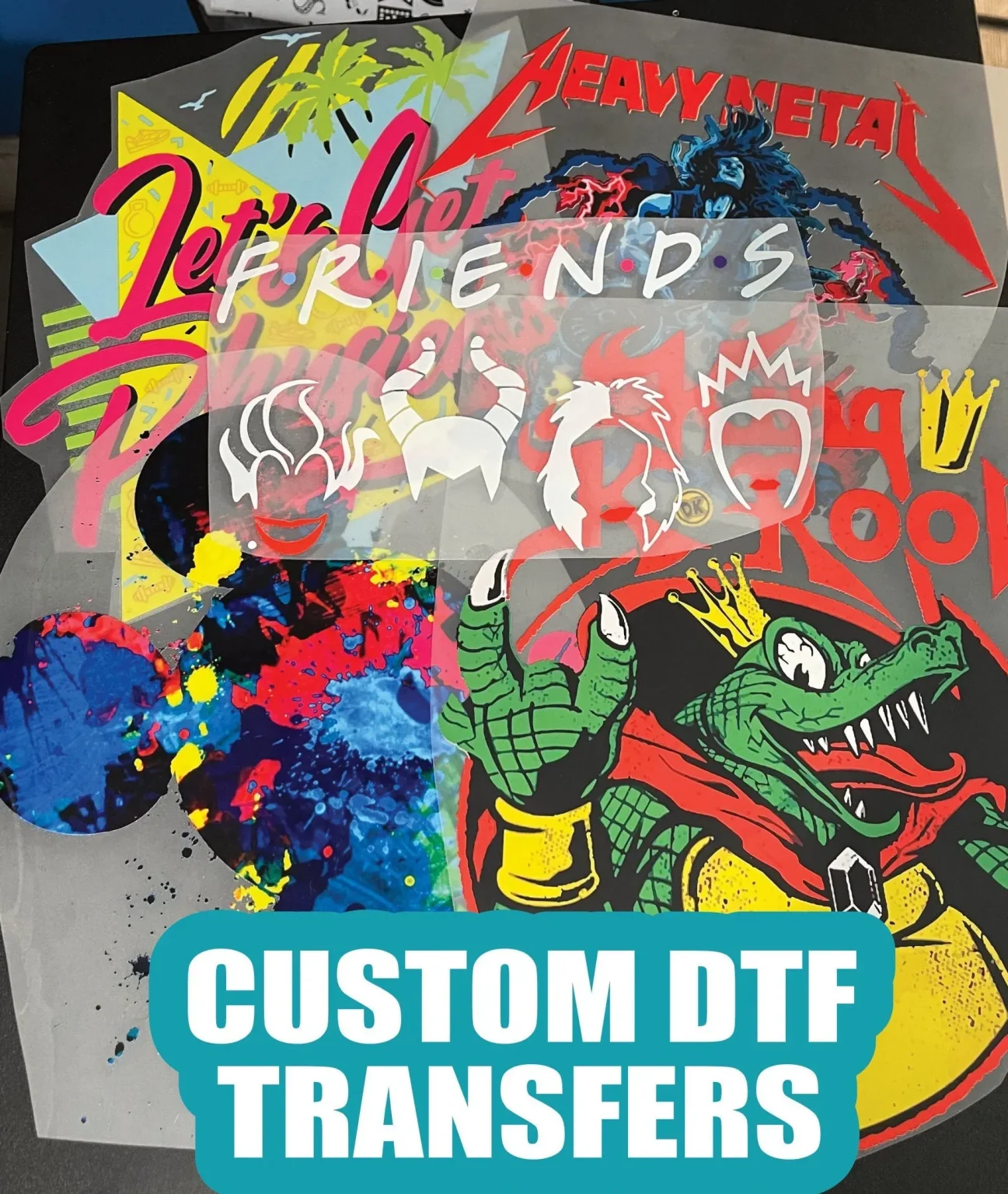

In the dynamic realm of custom printing, **DTF transfers** (Direct to Film transfers) are rapidly gaining attention for their unique advantages and capabilities. This innovative printing method combines digital printing technology with heat transfer processes to produce striking designs on a variety of materials. With businesses and individual creators embracing the print-on-demand trend, DTF transfers are shaping the future of custom printing, offering sustainable solutions through the use of eco-friendly water-based inks. As consumers increasingly seek personalized and high-quality products, the demand for DTF printing technology continues to soar. In this article, we will explore the enduring presence of DTF transfers, the technological advancements behind this method, and why it remains a preferred choice in the evolving printing landscape.

As the printing industry evolves, alternatives such as DTF printing technology and digital transfer methods have emerged, signaling a new era in custom printing solutions. Often categorized under the broad umbrella of garment printing techniques, DTF transfers are lauded for their ease of use and ability to produce vibrant prints on diverse fabrics. With a focus on sustainable printing practices, many enthusiasts and businesses are looking to eco-friendly options that allow for high-quality results without compromising environmental principles. Utilizing print-on-demand strategies, creators are finding that these transfer methods not only meet the growing demand for customization but also align perfectly with current trends in consumer preferences. In the following sections, we will delve deeper into the mechanics of DTF transfer printing and its significant impact on the market.

Understanding DTF Transfer Printing Technology

DTF transfer printing is an innovative digital printing process that revolutionizes traditional customization methods. By allowing vibrant designs to be printed directly onto a special film, this technology enables seamless transfers onto various fabrics, including cotton and polyester. Unlike conventional screen printing, which often requires tedious setup and adjustments, DTF printing simplifies the workflow, making it an excellent choice for small businesses and individual creators keen on exploring custom printing options.

One of the standout features of DTF technology is its versatility. It caters to a wide range of printing applications, from custom apparel to promotional merchandise, responding effectively to market demands. As consumers increasingly lean toward personalized products, DTF printing stands out by providing detailed, high-resolution graphics that capture the essence of individual designs, meeting the expectations of modern customers who prioritize quality and creativity.

The Rise of DTF Transfers in Custom Printing

The popularity of DTF transfers continues to soar as more businesses capitalize on the efficiency and affordability that this printing method offers. With lower startup costs and simplified processes, it becomes accessible for newcomers in the custom printing arena. The elimination of exorbitant expenses associated with traditional printing techniques has prompted countless small enterprises to adopt DTF technology, allowing them to produce high-quality prints without significant financial strain.

As demand for personalized and custom products surges, DTF printing is ideally positioned to meet these evolving consumer preferences. It’s not just about printing; it’s about enabling creativity in the marketplace. This technology allows individuals and businesses to create unique, tailor-made items that resonate with their audience, which is essential for standing out in today’s highly competitive environment.

Advancements in DTF Printing Technology

The landscape of DTF printing technology is rapidly changing, with significant advancements enhancing the quality and efficiency of the process. Modern DTF printers now use advanced water-based inks that promise improved adhesion, durability, and vibrancy, elevating the overall print quality. These innovations are vital for businesses looking to provide products that not only look good but also stand the test of time against regular wear and tear.

Furthermore, ongoing research into ink compositions and printing methods is paving the way for even more exciting developments in DTF technology. As manufacturers continue to refine their equipment and materials, we can expect enhancements in sustainability, such as reduced waste and a more eco-friendly approach to production. This aligns with the growing consumer inclination towards greener practices, further solidifying DTF printing’s relevance in a conscious market.

Eco-Friendly Benefits of DTF Printing

In today’s environmentally conscious world, the rise of DTF printing resonates well with the call for sustainable practices in manufacturing. DTF transfers utilize water-based inks, which are significantly less harmful than many solvent-based options typically found in traditional screen printing. This shift towards eco-friendliness reflects a broader trend where consumers actively seek products aligned with their values, making DTF a favorable choice for both producers and users alike.

Moreover, the lower environmental impact associated with DTF printing extends beyond just the inks used. The efficiencies gained through DTF technology lead to less resource wastage, whether in fabric or energy consumption. As more print businesses adopt sustainable practices, those utilizing DTF printing can effectively market their products as both high-quality and environmentally friendly, catering to a growing demographic of conscious consumers.

The Future of DTF Printing in Market Expansion

As the DTF printing market expands, it opens up new avenues for entrepreneurs and established businesses to explore diverse applications. Industry reports suggest that DTF technology is set to penetrate various sectors, including fashion apparel and promotional items, illuminating its potential beyond traditional markets. This versatility not only enhances demand but also fosters innovation across different creative fields.

With major shifts in consumer behavior towards customizable and personalized products, businesses leveraging DTF printing can effectively engage their audiences. The technology supports an array of applications, from everyday clothing to niche merchandise, reflecting the adaptability and growth potential of DTF printing as a staple in custom printing operations.

User-Friendly Innovations in DTF Printing

The accessibility of DTF printing is one of its remarkable features, drawing in enthusiasts and aspiring entrepreneurs alike. With user-friendly setups and minimal technical knowledge required, even novices in the printing industry can quickly learn to operate DTF printers. As highlighted by various industry sources, this ease of use encourages more individuals to participate in the custom printing space, which is crucial for fostering creativity and innovation.

Additionally, the engaging nature of customizing with DTF technology adds an enjoyable element to the creation process. As hobbyists and small business owners explore their design ideas, DTF printing enables them to bring their visions to life without overwhelming complexity. This inviting learning curve further solidifies DTF printing as a leading choice for those entering the world of custom printing.

Frequently Asked Questions

What are DTF transfers in custom printing?

DTF transfers, or Direct to Film transfers, refer to a digital printing technology that allows designs to be printed onto a special film and then transferred onto various fabrics using heat and pressure. This method is celebrated for producing vibrant prints on multiple fabric types, making it a popular choice in the realm of custom printing.

How does DTF printing technology compare to traditional methods?

DTF printing technology offers several advantages over traditional printing methods, such as ease of use and minimal setup requirements. Unlike screen printing, which requires extensive preparation and can be costly, DTF printing simplifies the process while maintaining high-quality output, making it ideal for custom printing needs.

Is DTF printing eco-friendly compared to other printing techniques?

Yes, DTF printing is considered more eco-friendly than traditional screen printing, as it utilizes water-based inks that have a lower environmental impact. This aligns with the growing consumer demand for sustainable printing solutions in the custom printing industry.

What types of materials can DTF transfers be applied to?

One of the key benefits of DTF transfers is their versatility. They can be applied to a wide range of materials, including cotton, polyester, and even blends. This makes DTF printing technology suitable for various custom printing applications, from fashion to promotional merchandise.

What is the future of DTF transfers in the custom printing market?

The future of DTF transfers looks promising, with expected market expansion due to ongoing technological advancements. As more businesses recognize the benefits of DTF printing, including efficiency and cost-effectiveness, it’s anticipated that this technology will play a crucial role in the evolution of custom printing.

How accessible is DTF printing for beginners in custom printing?

DTF printing is extremely accessible for beginners, thanks to user-friendly processes that require minimal training. Aspiring entrepreneurs and hobbyists can easily adopt DTF technology to create custom products, making it an appealing entry point into the custom printing industry.

| Key Points | Details |

|---|---|

| What is DTF Transfer Printing? | A digital print process where designs are printed onto a special film and then transferred onto materials using heat and pressure. |

| Growing Popularity | DTF transfers are gaining traction among businesses due to their efficiency and lack of intricate adjustments required in traditional printing. |

| Technological Advancements | Improvements in DTF transfers have led to high-resolution prints and better environmental sustainability through new water-based inks. |

| Environmental Considerations | DTF transfers use water-based inks that are less harmful to the environment, appealing to eco-conscious consumers. |

| Market Expansion | The DTF printing market is expected to grow, with decreasing costs making it more accessible to new entrants in the custom printing arena. |

| User-Friendly Processes | DTF printing is user-friendly, allowing novices to create unique designs without extensive training. |

| Economic Resilience | Low startup costs and minimal maintenance requirements make DTF printing an attractive option for entrepreneurs. |

| Future Trends To Watch | Expect continuous technological advancements and increased opportunities for personalization in the DTF printing sector. |

Summary

DTF transfers are revolutionizing the world of custom printing, providing efficient, high-quality, and eco-friendly solutions. The growing popularity of DTF transfers is backed by advances in technology that enhance print quality while ensuring environmental sustainability. As market demands evolve, DTF printing is becoming a preferred choice for businesses looking to meet consumer expectations for personalized and sustainable products. With its expanding accessibility, the future of DTF transfers looks bright, making it an essential element in the custom printing landscape.