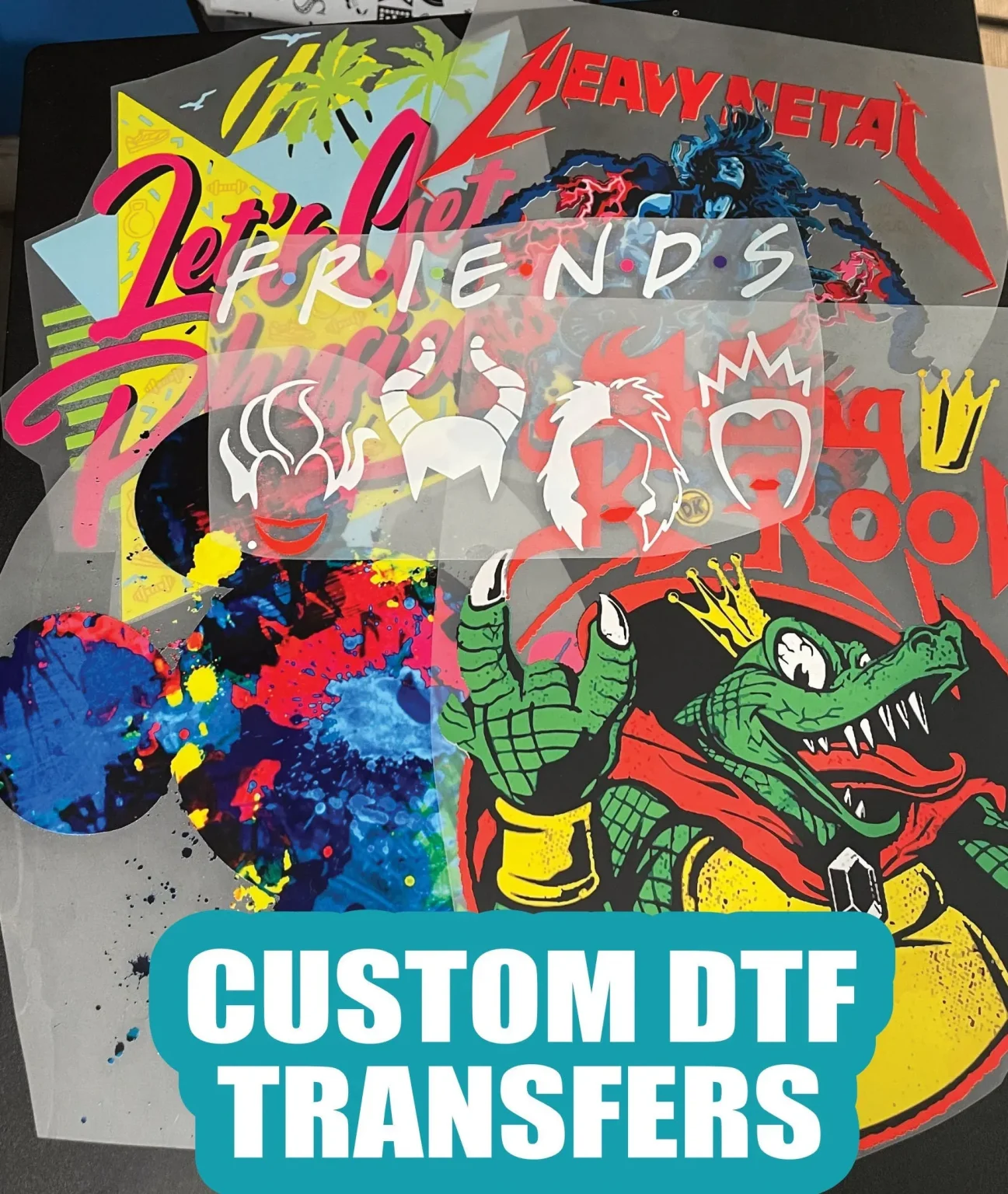

DTF transfers, or Direct to Film printing, are revolutionizing the printing landscape by offering an innovative alternative to traditional methods like screen printing. This cutting-edge printing technology enables businesses to produce stunning custom apparel with vibrant colors and exceptional print quality that meets the ever-increasing demands of customers. By leveraging DTF transfers, printing companies can enjoy faster turnaround times and the versatility to print on a wide range of materials, including cotton and polyester blends. As we explore the transformative benefits of DTF technology, it becomes clear why it is quickly becoming a go-to solution for custom apparel printing. From startups to established enterprises, adopting DTF transfers is not just a trend but a strategic move towards enhancing operational efficiency and product offerings.

Direct to Film (DTF) printing represents a groundbreaking advancement in the world of printing technology, providing a fresh approach to creating custom prints. This innovative printing method allows for high-quality images to be transferred onto various substrates, making it a flexible choice for businesses looking to cater to diverse market needs. With its exceptional ability to produce detailed prints, DTF printing is emerging as one of the most effective screen printing alternatives available today. The process not only accelerates production but also maintains the durability and vibrancy that customers demand, ensuring satisfaction with every order. As printing businesses evolve, understanding and leveraging the benefits of DTF can lead to substantial growth and industry leadership.

The Advantages of Direct To Film (DTF) Transfers

Direct To Film (DTF) transfers have revolutionized the printing landscape by offering numerous advantages over traditional methods. One of the primary benefits is the vibrant color reproduction that DTF provides, allowing intricate designs to come to life on various substrates. This printing technology is particularly effective on darker materials where screen printing may struggle to achieve the same level of vibrancy. Additionally, the process is user-friendly, requiring less collaboration than other techniques, ensuring that even companies new to printing can quickly adopt it.

DTF transfers also promise faster turnaround times compared to conventional printing options. This efficiency is crucial for businesses looking to fulfill orders promptly, thereby improving customer satisfaction. As print demands fluctuate, DTF’s flexibility allows for a seamless adjustment of production schedules without sacrificing quality, catering to urgent requests and last-minute orders.

Exploring Screen Printing Alternatives

The limitations of traditional screen printing often hinder printing businesses from fully meeting customer expectations. Screen printing is notorious for its lengthy setup times and capacity restrictions when it comes to intricate designs and color variations. Consequently, many businesses are exploring alternatives like DTF transfers that overcome these hurdles. DTF technology offers the flexibility to print a diverse array of colors and designs without the restrictive setup associated with screen printing, positioning it as a highly attractive alternative.

Moreover, DTF transfers enable businesses to venture into custom apparel printing without the hefty investments typical of screen printing equipment and space. By utilizing DTF printing, companies can diversify their product offerings efficiently, catering to specific customer demands while maintaining quality.

Enhancing Print Quality with DTF Technology

Print quality is paramount in the competitive printing industry, and DTF transfers consistently deliver exceptional results. This technology employs specialized inks and films that allow for sharper images and bolder colors, elevating the standard of custom printed goods. Unlike other methods, DTF printing produces high-resolution outputs that are critical for businesses aiming to attract discerning customers.

Furthermore, the durability of DTF prints enhances their appeal and reliability. Prints created through this process resist common issues like cracking or fading, ensuring that customers receive merchandise that withstands the test of time. This longevity not only boosts customer satisfaction but also encourages repeat business, a key factor in sustaining a resilient printing enterprise.

DTF Printing: A Game-Changer for Small Businesses

For small businesses, adopting DTF technology can represent a significant turning point in their operations. With lower initial investment costs and a less complex setup process, DTF printing opens up a realm of possibilities for entrepreneurs aiming to make their mark in the custom printing market. The ease of transitioning between different designs allows these businesses to remain agile and responsive to market trends.

Moreover, small printing enterprises can leverage DTF technology to produce niche products tailored to specific customer demographics. This adaptability empowers them to carve out unique business identities in a crowded marketplace, positioning themselves as leaders in custom apparel and promotional merchandise.

The Role of DTF in Custom Apparel Printing

Custom apparel printing has witnessed a surge in demand, and DTF transfers have become a vital tool for businesses eager to meet this need. This technology is especially effective for creating detailed designs that showcase brand identities, making it easier for companies to offer personalized solutions to their clients. Whether for sports teams, corporate branding, or events, DTF printing facilitates the production of high-quality, bespoke apparel that resonates with consumers.

In addition to versatility, DTF transfers allow for rapid prototyping and production, helping businesses to test market responses quickly. This ability to adapt immediately to client feedback is a distinct advantage over traditional printing techniques, which often require longer lead times and commitment to larger production runs.

Future Trends in DTF Printing Technology

As DTF technology continues to evolve, several trends are shaping the future of this printing method. With ongoing advancements in inks and printing machines, we can expect improved efficiency, reduced costs, and even greater versatility in material applications. These enhancements will further position DTF as a preferred choice among printing businesses striving for excellence in their output.

Furthermore, the integration of automated solutions and artificial intelligence in the printing process may bring a transformative impact, simplifying job management and expanding operational capabilities. This potential for technological innovation suggests that DTF will not only sustain its relevance but thrive, catering to an ever-more demanding market landscape.

Frequently Asked Questions

What is Direct To Film (DTF) printing and how does it work?

Direct To Film (DTF) printing is a revolutionary method that involves printing designs onto a special PET film, which is then transferred onto fabrics using heat and adhesive powder. This process allows for vibrant colors and high-resolution prints suitable for a variety of materials, including cotton and polyester.

Why should businesses consider DTF transfers over traditional screen printing?

Businesses should consider DTF transfers as they offer greater versatility, faster turnaround times, and higher print quality compared to traditional screen printing. DTF technology is adaptable for various substrates and produces vibrant, long-lasting designs that satisfy customer demands.

How does the print quality of DTF transfers compare to other printing methods?

DTF transfers are known for their outstanding print quality, producing vibrant colors and intricate details that can rival or surpass other methods, such as screen printing and sublimation. This high-quality output makes DTF an attractive choice for custom apparel printing.

What materials can be used with DTF transfers?

DTF transfers are compatible with a wide range of materials, including cotton, polyester, and blends. This versatility allows businesses to expand their product offerings without needing additional equipment, making DTF a flexible printing technology.

What are the operational efficiencies gained from using DTF printing technology?

Incorporating DTF printing allows for quicker switchovers between designs, reducing setup times and improving productivity. This efficiency enhances a business’s ability to fulfill customer orders promptly, which is essential for maintaining a loyal client base.

Are DTF transfers durable, and how do they hold up over time?

Yes, DTF transfers are highly durable, resisting fading, cracking, and peeling even after multiple washes. This durability leads to increased customer satisfaction and repeat business, as clients appreciate the long-lasting quality of their printed goods.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | Direct to Film (DTF) is a printing method where designs are printed onto a special film suitable for a variety of substrates, allowing for high-quality prints with vibrant colors and fine details. |

| Process Overview | In DTF printing, designs are printed onto PET film using specialized inks, then adhesive powder is applied and heat-treated to ensure durability when transferred to fabrics. |

| Market Demand | The demand for DTF printing is rapidly increasing as businesses seek to meet consumer expectations for quality and customization, leading to significant revenue growth projections in the market. |

| Technological Innovations | Advancements such as the Procolored F13 Panda L1800 printer enhance print quality and efficiency, allowing for greater versatility in product offerings. |

| Operational Efficiencies | DTF printing simplifies operations by reducing setup time and allowing quick design changes, improving productivity and order fulfillment. |

| Versatility | DTF transfers can be used on a wide range of products, from apparel to promotional items, enabling businesses to adapt to market demands without significant investment. |

| Quality and Durability | DTF prints are known for vibrant colors and intricate designs that resist fading and peeling, contributing to customer satisfaction and repeat business. |

Summary

DTF transfers are revolutionizing the printing business by providing a cutting-edge solution that meets the increasing demand for high-quality and customizable products. This innovative printing technology not only enhances print quality and production efficiency but also expands product versatility, allowing businesses to cater to a wider market. As competition continues to grow within the industry, adopting DTF transfers is essential for businesses to stay ahead and thrive. Embracing DTF technology ensures a robust market presence and paves the way for future success.