In the dynamic world of custom apparel, DTF transfers have emerged as a revolutionary technique that is transforming how designs are applied to fabrics. Short for Direct to Film printing, this method involves transferring vibrant graphics directly onto a film, making it easier than ever to create stunning, high-quality prints. Businesses are increasingly turning to the DTF printing process for its cost-effectiveness and versatility, catering to diverse design needs without compromising on quality. With the increasing demand for personalized clothing options, understanding the benefits of DTF transfers can give your business a competitive edge. This guide will delve into why DTF transfers are a favorite among customers and how you can seamlessly integrate this innovative service into your offerings.

Also known as Direct to Film transfers, this modern printing method is gaining traction in the custom garment industry for its ability to produce detailed and colorful designs. Unlike traditional techniques, this process simplifies the creation of intricate prints on a variety of fabric types, making it a preferred choice for businesses looking to offer personalized apparel solutions. The DTF printing technique not only ensures enhanced durability and resistance to wear but also presents a budget-friendly option for small and large-scale operations alike. As more customers seek unique clothing items, understanding how to utilize DTF transfers becomes essential for shops aiming to meet these demands effectively. In this exploration of DTF technology, we will uncover its practical applications, advantages, and how to best implement these transfers into your product lineup.

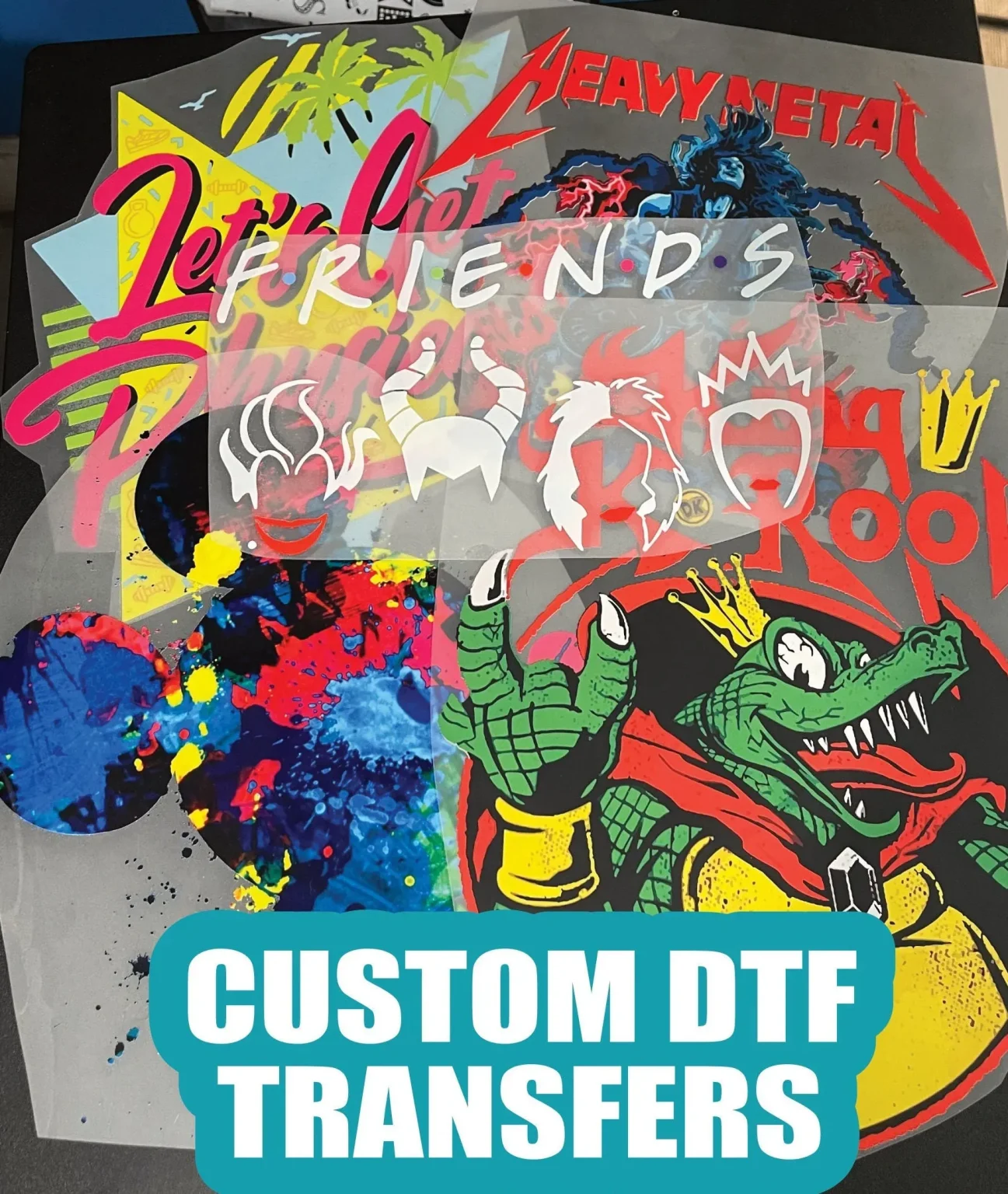

Understanding the DTF Printing Process

The Direct to Film (DTF) printing process is revolutionizing the way businesses approach custom apparel, offering a unique method for transferring high-quality images onto fabric. Essentially, this technique involves printing designs onto a special film using specialized inks, which are then adhered to the chosen material through heat and pressure. What sets DTF apart from other methods, like screen printing, is its ability to produce intricate designs with vibrant colors, making it particularly appealing for complex artwork. This proven versatility allows businesses to cater to diverse customer requests, from bold graphics on t-shirts to detailed designs on bags.

In addition to delivering high-quality imagery, the DTF printing process is known for its efficiency. Once the initial setup is completed—including design preparation and film printing—the actual transfer to fabric can be achieved quickly, enabling a faster turnaround on orders. For businesses, this means less downtime and the ability to meet customer demands promptly. As a result, the DTF printing process not only enhances creativity but also streamlines production workflows, making it a smart investment for any custom apparel operation.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique where graphics are printed onto a specialized film. This film is then used to transfer vibrant designs onto various fabrics using heat and pressure, allowing for intricate artwork on custom apparel.

What are the key benefits of using DTF transfers for custom apparel?

The benefits of DTF transfers include high-quality prints with vibrant colors and details, versatility across different fabrics, durability against fading and cracking, cost-effectiveness for small batches, and ease of use in the printing process, making them ideal for custom apparel.

How do I start using DTF transfers in my printing business?

To start using DTF transfers, invest in quality DTF printing equipment, including a DTF printer, transfer film, and adhesive powder. Familiarize your team with design software for creating graphics, ensure staff training on the printing process, and develop an effective marketing strategy for your services.

Why are DTF transfers becoming popular in the custom apparel industry?

DTF transfers are gaining popularity due to their ability to produce high-quality, personalized designs efficiently, which satisfies the increasing consumer demand for unique and custom apparel, particularly in the growing e-commerce market.

What types of fabrics can DTF transfers be applied to?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This adaptability allows businesses to create custom apparel for various items like t-shirts, hoodies, and bags.

Can DTF transfers compete with traditional printing methods?

Yes, DTF transfers can effectively compete with traditional printing methods such as screen printing due to their superior print quality, lower setup costs for small runs, longer-lasting prints, and the flexibility to create detailed designs, making them a preferred choice for many businesses.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A modern printing technique where graphics are printed on a special film and transferred onto fabrics using heat and pressure. |

| Advantages | High quality, versatile, durable, cost-effective, and easy to use. |

| How to Offer DTF Transfers | Invest in equipment, utilize design software, train staff, and implement effective marketing strategies. |

| Trends and Popularity | Increased demand for personalized apparel and opportunities in online marketplaces. |

Summary

DTF Transfers have become a prominent choice for many businesses and customers in the custom apparel industry. This innovative printing method offers numerous advantages, including high-quality outputs, versatility across different fabric types, and exceptional durability. By effectively implementing DTF Transfers into your business operations, you can meet the rising demand for unique custom designs, hitting the sweet spot between affordability and quality. To stay competitive, it’s vital to invest in the right equipment, provide thorough training, and utilize targeted marketing strategies. Embracing DTF Transfers positions your business as a forward-thinking entity in a rapidly evolving market, ensuring customer satisfaction and loyalty that drives repeat business.